Page 1 of 1

Cylinder head nuts tightening sequence.

Posted: Fri Feb 21, 2025 12:51 pm

by Mr. V

I have found three different tightening sequences in various manuals. The one I fancy for my 1275 midget 940 head is the clockwise spiral starting at the middle stud on the o/s of the head (which is not the one in the Haynes Midget manual).

Any pearls of wisdom?

PS. The engine has dimpled studs, but plain nuts and thick washers. I have bought flanged HT nuts. Am I therefore OK for 50lb ft?

Re: Cylinder head nuts tightening sequence.

Posted: Fri Feb 21, 2025 7:02 pm

by philthehill

Forget the Haines manual and get a proper BMC or BL workshop manual for the correct information.

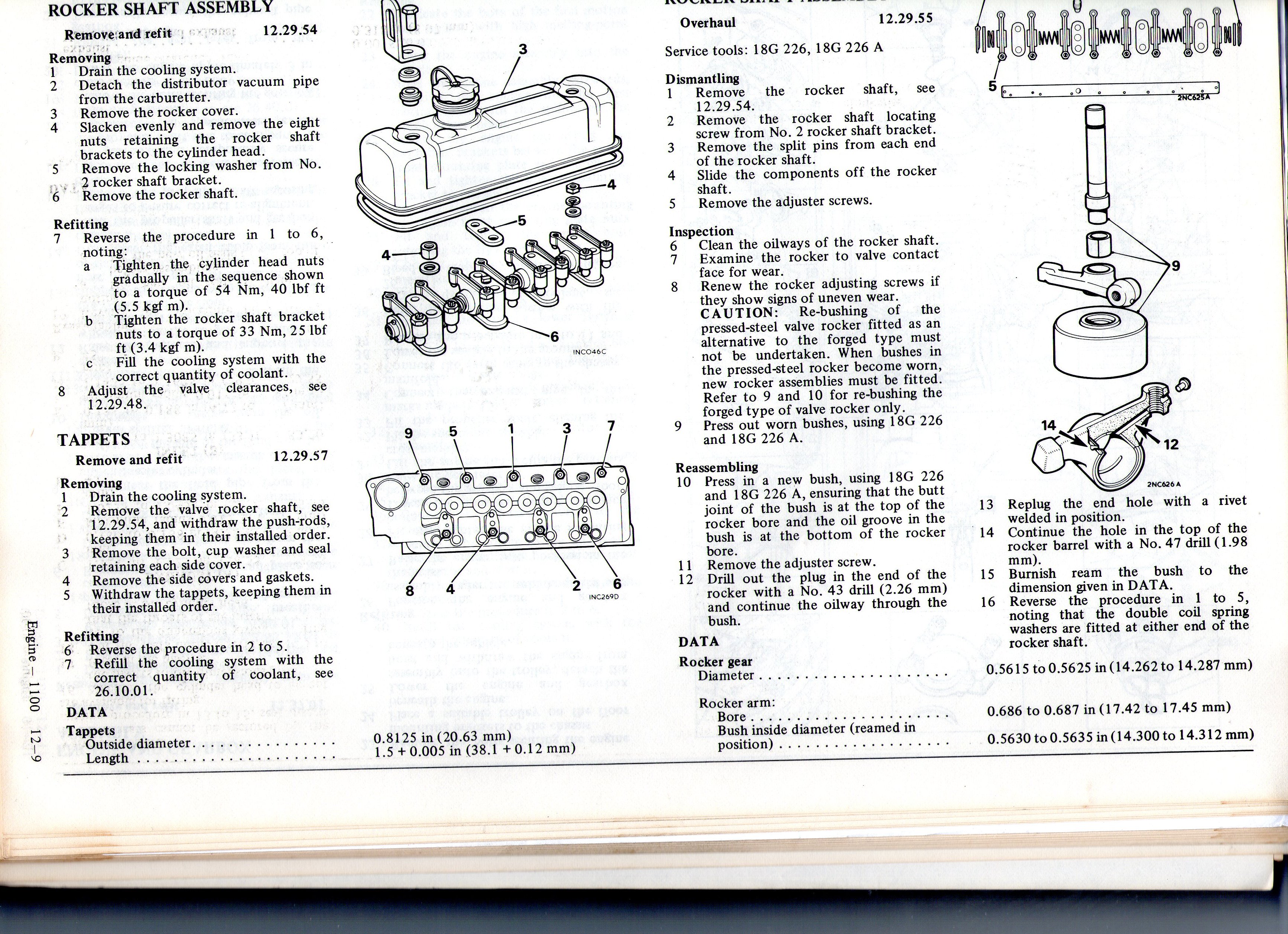

Here is the correct sequence for tightening the cylinder head studs/nuts from a genuine BL manual.

- head stud tightening.jpg (1.77 MiB) Viewed 3015 times

As you have dimpled studs and flanged nuts you can tighten to 50lbf ft. Do not lubricate the nuts - fit them dry otherwise you will end up with the wrong torque/tightness.

Re: Cylinder head nuts tightening sequence.

Posted: Fri Feb 21, 2025 9:30 pm

by Mr. V

Thanks Phil. That's the same as my Haynes Midget manual. Much appreciated. I liked the spiral pattern because it's easy to remember! However, I will follow your advice with confidence.

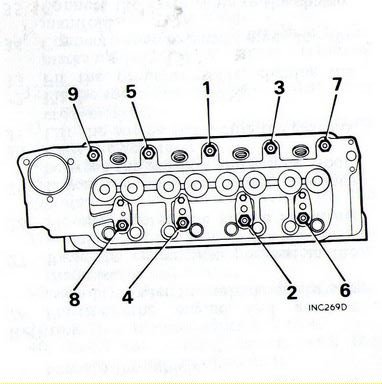

I assume you tighten each rocker shaft stud nut (up to 25 ft lb?) at the same time as it's fellow head nut.

Re: Cylinder head nuts tightening sequence.

Posted: Fri Feb 21, 2025 10:16 pm

by philthehill

Tighten the head nuts first in the correct sequence and then tighten the rocker pedestal nuts to 25lbf ft.

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 9:40 am

by Mr. V

OK. Got you. Thanks.

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 9:46 am

by svenedin

It's a good idea to print out the diagram nice and large as fiddling with a phone to see the picture is not a great idea with oily hands! You can then use that sheet of paper to tick off each valve as you adjust the clearances.

Stephen

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 12:25 pm

by geoberni

philthehill wrote: ↑Fri Feb 21, 2025 7:02 pm

Forget the Haines manual and get a proper BMC or BL workshop manual for the correct information.

Phil,

as an experienced/knowledgeable person on such engines, do you know why there is a difference between different capacities of A Series engine?

To my mind, as they are just derivatives of the same design, I don't see a reason for it altering.

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 2:31 pm

by philthehill

If you are referring to the cylinder head stud/nut torque - the main difference between the 'A' Series and the 'A' Plus series engine is the power output of later engines which requires the head to be torqued down tighter so requiring better head studs and nuts. The most obvious example is the Cooper 'S' which famously kept blowing head gaskets at the front and at the rear where the distance between the studs is greatest. To overcome the problem BMC introduced a 10th 3/8" stud at the rear and a 5/16" bolt at the front. The bolt was fitted at the front with reduced torque (25lbf ft) because the head casting is very thin in that area. Many of the bolts have been replaced by 3/8" studs my own included but the stud still has to be torqued to 25lbf ft otherwise there is a possibility of the head breaking around the thermostat area.

Many of the ex factory Minor head studs are now around 60 years old. They do not last forever and do stretch. In my opinion it is better to replace the original studs with the later high tensile studs (with dimple in the top, a conical top or a 'Y' stamped into the top) and the flanged nuts. The stud holes in the block should be lightly countersunk to remove any pulling up of the block around the stud threads which can hinder the head being pulled down correctly. Whilst the likes of ARP high tensile studs and nuts are expensive to purchase the high tensile studs and flanged nuts as originally fitted to 'A' Plus engines can be sourced S/H from the likes of 'e' bay. I have used S/H high tensile studs and flanged nuts for many years without problem even with higher compression engines. With my race engine I use ARP studs, 12 point nuts and special washers. Over the years I have saved several sets of high tensile studs and flanged nuts from the likes of Morris Marina engines for use future use with 'A' Series engines of all capacities. When I rebuild a 'A' Series engine the standard ex factory non 'A' Plus head studs are destined for the scrap bin as that is were they belong.

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 3:17 pm

by geoberni

Sorry Phill, having read it back I realise I didn't make myself clear; it was the different manuals, for different size A series engines, giving a different tightening sequence.

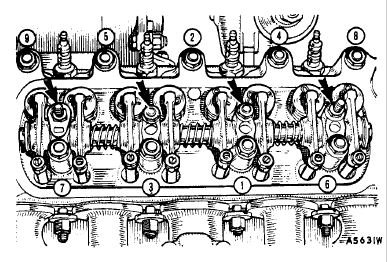

The Minor manual shows this:

- Minor Sequence.JPG (49.6 KiB) Viewed 2819 times

While the one you posted was this:

- Phills image.JPG (39.09 KiB) Viewed 2819 times

Just curious as to why they might be different...

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 4:26 pm

by philthehill

No problem

I would suggest that there is a difference because it was realised that the later sequence is better as it squeezes the gasket outwards towards the front and rear of the head/block. This sequence of squeezing of the gasket is better as it ensures that the gasket is laid as it should be with no possibility of creasing (sic) between the studs as could happen with the early sequence.

I have always used the later sequence even way back when there was no large block 'A' Series.

Phil

Re: Cylinder head nuts tightening sequence.

Posted: Sat Feb 22, 2025 5:38 pm

by geoberni

philthehill wrote: ↑Sat Feb 22, 2025 4:26 pm

No problem

I would suggest that there is a difference because it was realised that the later sequence is better as it squeezes the gasket outwards towards the front and rear of the head/block. This sequence of squeezing of the gasket is better as it ensures that the gasket is laid as it should be with no possibility of creasing (sic) between the studs as could happen with the early sequence.

I have always used the later sequence even way back when there was no large block 'A' Series.

Phil

Makes sense.