Page 1 of 1

Clutch fork orientation

Posted: Sat Nov 02, 2024 2:48 pm

by tomb1963

Hi All,

Nearly two years ago, the engine and gearbox on our 1969 Morris 1000 Traveller were removed, degreased, cleaned, painted, gaskets replaced etc.

We also fitted a new three part clutch (Borg and Beck) from a reputable Morris Minor parts supplier along with most of the clutch linkage components. My son turned a new clutch pedal shaft and all the associated bushes were also replaced. However we've never been able to set up the clutch to our satisfaction.

Tomorrow we are going to have a really good look at everything, including looking inside the gearbox bell housing using the LHS fork hole. One of the things to look for is whether the fork is in the correct orientation as this may prevent the clutch release carbon thingy from fully engaging with the pressure plate. Can anyone detail the correct orientation, i.e. should the 'cut-outs' for the carbon bit retaining clips be facing the flywheel so that the part is closer to the plate?

Any help and suggestions would be gratefully received.

Re: Clutch fork orientation

Posted: Sat Nov 02, 2024 3:17 pm

by Chipper

This YouTube clip shows how it is assembled (from around 1:50 onwards).

https://www.youtube.com/watch?v=9SNKUz_E78g

Re: Clutch fork orientation

Posted: Sat Nov 02, 2024 3:31 pm

by tomb1963

Thank you for your very quick reply.

It is therefore possible that the carbon thingy it too far away from the pressure plate if I have the fork in the incorrect orientation: something to check for tomorrow. I'll be annoyed with myself if that's the issue!

Re: Clutch fork orientation

Posted: Sat Nov 02, 2024 6:29 pm

by mowogg

What is wrong with the clutch- you say you cannot set it up to your satisfaction?

Does it work or does it judder?

Re: Clutch fork orientation

Posted: Sun Nov 03, 2024 10:59 am

by geoberni

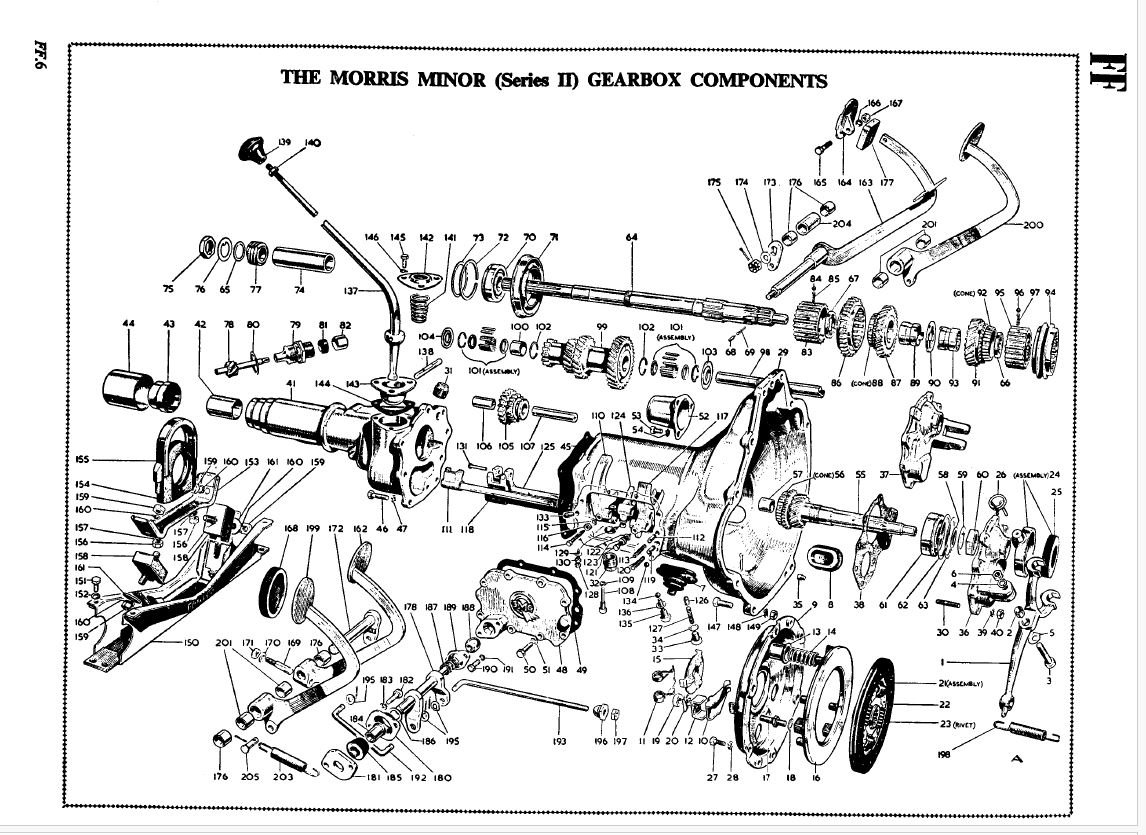

Orientation of the Clutch Lever is clearly illustrated in the Workshop Manual exploded view:

- gearbox exploded view.JPG (248.44 KiB) Viewed 3551 times

.

It has to be that way around so that a Clutch Thrust Ring/Bearing can be changed without removing the lever arm.

Re: Clutch fork orientation

Posted: Mon Nov 04, 2024 10:30 am

by olonas

Hopefully the o.p. hasn't fitted a 948cc lever? There's a difference depnding on 'box and engine.Images stolen from ESM. However, the carbon release bearings are not interchangeable.

- lever 1098.jpg (37 KiB) Viewed 3506 times

- lever 948.jpg (12.95 KiB) Viewed 3506 times

Re: Clutch fork orientation

Posted: Mon Nov 18, 2024 6:21 pm

by Chipper

Also beware that the carbon thrust bearings come in various different sizes/throwout depths, depending on whether they are intended for 803/948/1098/1275cc.

Re: Clutch fork orientation

Posted: Sat May 24, 2025 11:35 am

by tomb1963

Update: after removing the engine last November it was found that the yoke had been refitted correctly.

The actual problem was that the clutch pressure plate had gone wonky, just like in the thread

viewtopic.php?p=697824&sid=62d6a8300e3c ... b2#p697824.

The supplier sent a new clutch kit without quibble and the pressure plate was replaced as the other clutch components had done less than 2000 miles.

The exact same thing happened again yesterday: my son was not able to disengage the gearbox drive during a journey home which included stopping at some traffic lights in a town so had to crash the gears.

On getting home, my son soon worked out that one of the three 14mm nuts on the clutch pressure plate had come loose and he was able to tighten up the same through the hole in the bell housing through which the yoke for a LHD model would pass: he removed the spark plugs in order to turn the engine to the appropriate positions. A test drive showed that the clutch was operational once more.

He looked at the plate previously fitted that luckily had not yet gone down to the tip. He deduced that the same had happened before. He has marked up the offending nut on the fitted plate and will peen the same in order to lock it into position once he can find a suitably long centre punch.

So it may be a good idea to, before fitting a new Borg and Beck clutch pressure plate, check that all three nuts are tight and find some way of locking them.

Perhaps we will now also strip down the other plate and re-assemble as a spare.

Re: Clutch fork orientation

Posted: Sat May 24, 2025 6:27 pm

by philthehill

I would suggest that you remove the clutch cover and check that all three fingers are at the same height. It is not unknown for the clutch fingers to be set at different heights (ex factory) which could (and most probably will) lead to the staked nuts coming undone. The nuts must be double staked into the grooves of the threaded link pin. If they are not double staked the possibility/risk of the nut coming undone is increased.

To reiterate the fingers must be set at the same height as per the factory specification. Whilst it is possible to set the fingers without the special tool it is best if the Sykes Pickavant dummy clutch tool Pt No: 204 is used.

Re: Clutch fork orientation

Posted: Sat May 24, 2025 9:53 pm

by les

Clutch cover should be torqued up, rather than just tightened ! ———25ft lb. Then they won’t come undone, ——- and I thought they were bolts.

Re: Clutch fork orientation

Posted: Sun May 25, 2025 8:10 am

by philthehill

Les

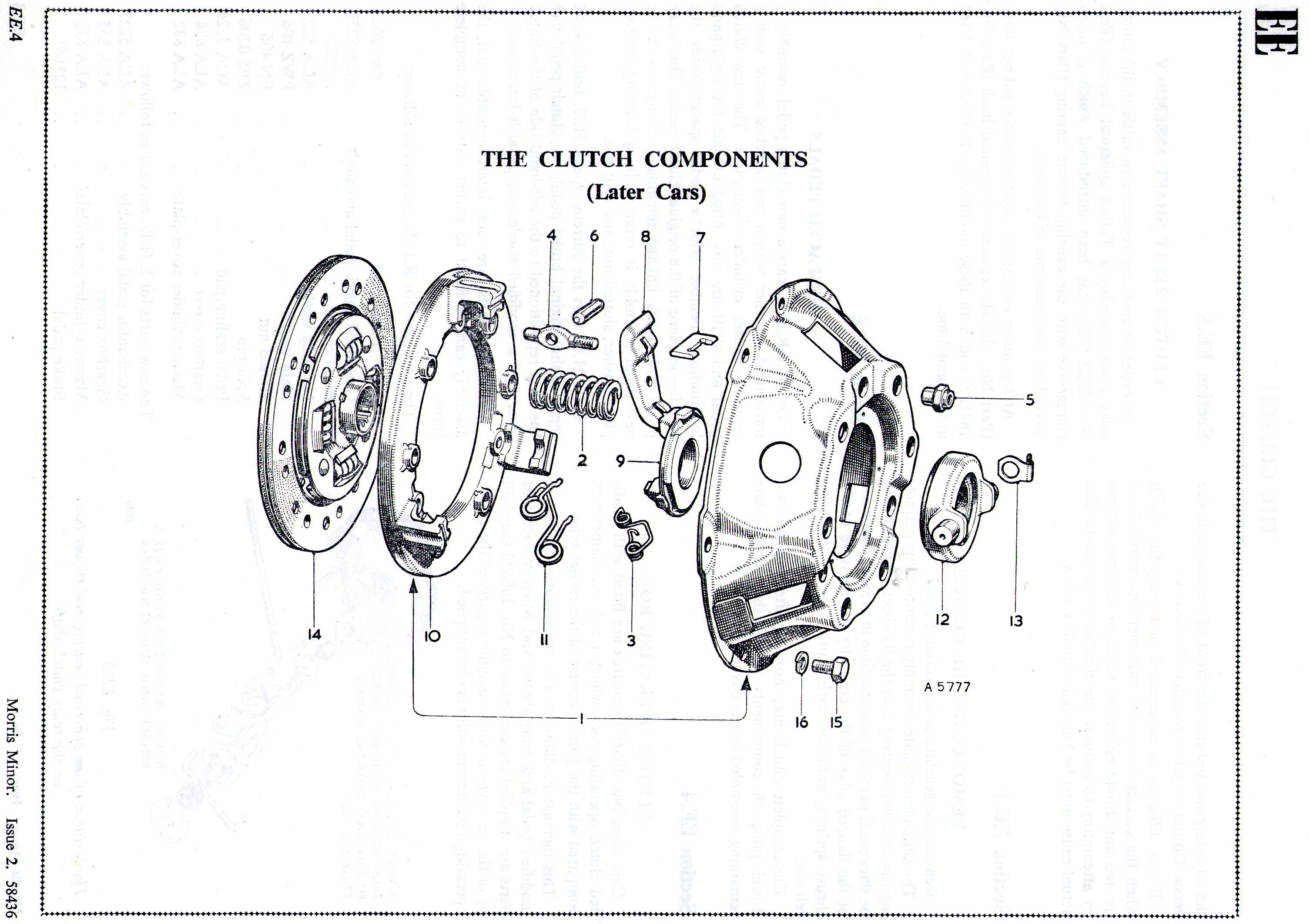

I believe that the OP is referring to the three nuts (item No: 5 in the diagram below) that set the height of the release levers/fingers (item No: 8 in the diagram below) that move the pressure plate within the clutch cover.

Those three nuts are not torqued to any setting. They are turned to raise or lower the fingers which are set to a specific height relative to the clutch cover being used. Once the fingers are set at the correct height the adjusting nuts are secured by staking them into the grooves of the eyebolt (item No: 4 in the diagram below). The process of setting the release levers is set out in BMC Wksp Manual AKD530 Section EE 8.

I am fortunate in having the Sykes Pickavant clutch special tool and can set and adjust the clutch finger height if and as required.

Phil

- clutch cover 22.jpg (794.58 KiB) Viewed 1511 times

Re: Clutch fork orientation

Posted: Sun May 25, 2025 10:05 am

by les

In that case, my apologies to tomb1963.

Re: Clutch fork orientation

Posted: Sun Jun 01, 2025 11:50 am

by tomb1963

Just to let all know that my son's unscientific approach seems to have worked (for now). Three 50 mile round trips up and down the Lincolnshire Wolds and the clutch is still operating fine. Only time will tell if we have to the job correctly, i.e. set the heights of the fingers.

Thank you to all that have offered advice.