Page 1 of 2

Crankcase Breathing

Posted: Fri Sep 13, 2024 9:32 am

by Mr. V

Having read various threads on this subject the conclusion is that it is a good thing to have lower than atmospheric pressure in the crankcase, mostly due to the scroll between crankcase and clutch housing benefitting from this arrangement, as far as oil leakage is concerned.

However, this raises two questions in my mind, which are:

1). Would not the logical corollary be to have an unvented oil filler cap, so all the air is drawn through the scroll (and, possibly, the dipstick tube), ensuring the lowest practicable crankcase pressure?

2). Would not the result of all this increase the amount of clutch dust being drawn into the crankcase, which must be even more undesirable than with the conventional, vented arrangement?

The thought of any clutch material being drawn into the crankcase makes me shudder, so maybe the ideal solution would be a conventional lip seal rubbing on a machined part of the crankshaft, which is, admittedly, expensive and time consuming?

The horror, the horror!

Any ideas?

Re: Crankcase Breathing

Posted: Fri Sep 13, 2024 11:31 am

by Bill_qaz

Or just keep oil level half way between min and max, so not overfilled. Keep whichever breather your year has correctly maintained and don't worry about a few drips from the the jiggle pin.

I could buy lots of oil cheaper than rear main seal conversion cost

Re: Crankcase Breathing

Posted: Fri Sep 13, 2024 12:15 pm

by jaekl

First and fore most blow by gases can be explosive and that is why the crankcase needs to be vented. Secondly, the rear main has a drain to remove the oil that comes out of the bearing. A vacuum is not needed to pull the oil preventing it from escaping, just a lack of pressure. Once the pressure rises, it PUSHES the oil out anywhere and everywhere. The rear main is one of the lower spots, so likely the first area. Ideally, the void of the rear main should be atmospheric, so that nothing is pulled in from the bell housing. Some fill caps are vented and some are not. It depends on the vintage. If the system that uses the vented cap and the cap has not been changed, it could be clogged, which could be causing the crankcase gases to build faster than air can be pulled in through the scroll.

Re: Crankcase Breathing

Posted: Fri Sep 13, 2024 9:49 pm

by BaritoneUke

There are some interesting posts if you search on pcv breathing system (some thing like positive crank ventilation I think) and some engine (minis?) had a pcv valve...quite rare now but mini spares does one at 75 squid

Some rate it as the bees knees of crankcase breathing and oil control...

Re: Crankcase Breathing

Posted: Fri Sep 13, 2024 10:12 pm

by svenedin

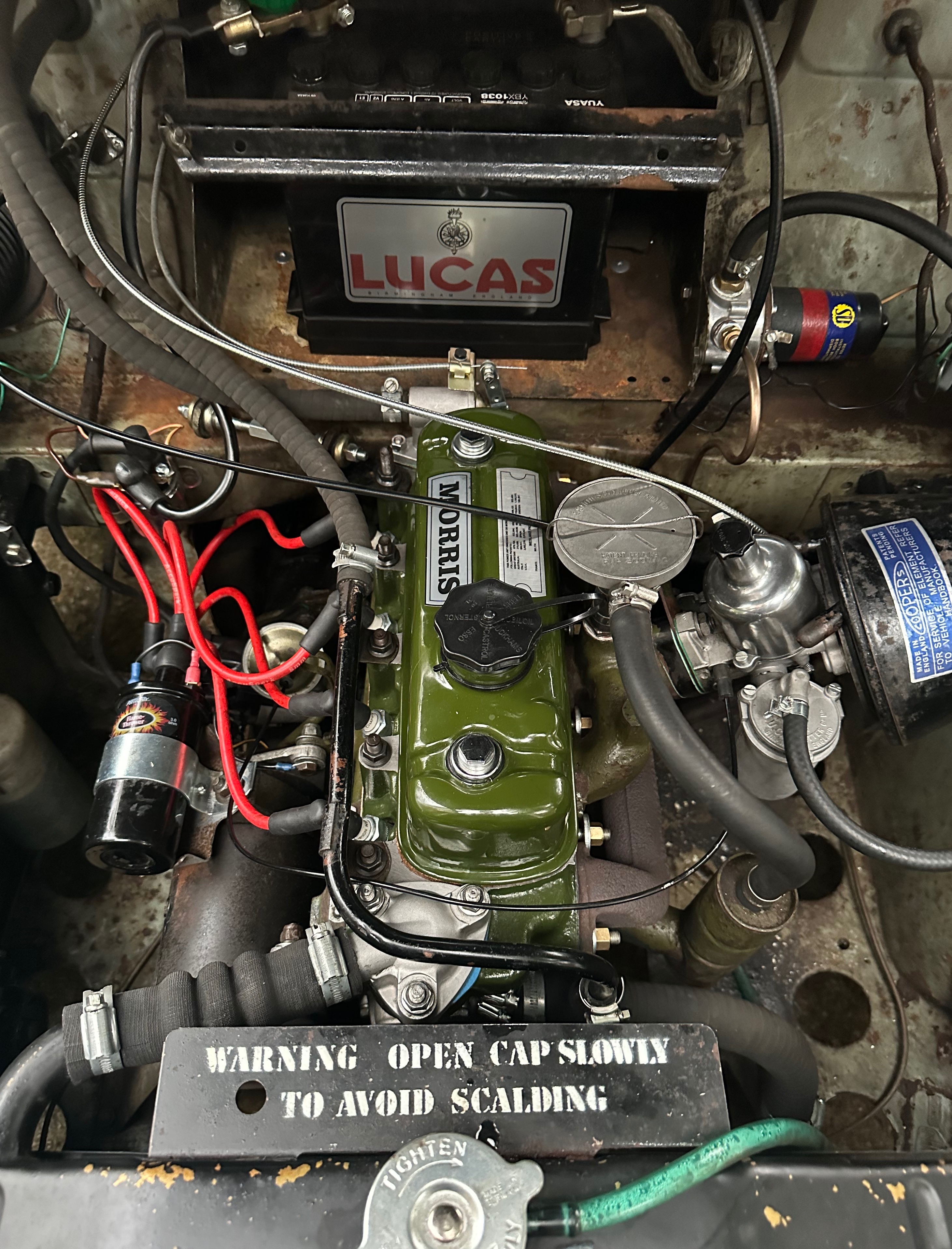

Morris Minors also had Smiths PCV valves but as far as I know only on 1969 (possibly also late 1968) cars. My 1969 car has a PCV valve. After 1969 the breathing was changed so that a "breather" version of the HS2 carburettor was used. This carburettor has a breather inlet connection.

The Morris Minors with a PCV valve have a different manifold (12A1097) that has provision for the PCV inlet and the bracket that holds the PCV valve in place. These manifolds are rather rare but sometimes they have been fitted to cars that never had a PCV valve because they provide a convenient connection for an after-market brake servo.

The Smiths PCV valve works very well but does need the correct manifold to mount it. Unfortunately, if the rubber diaphragm inside the PCV valve fails (which it can do with just a small hole) this causes the engine to run extremely lean (air is drawn in) and the crankcase ventilation to fail completely (oil leaks everywhere). Due to this issue it was thought simpler and more reliable to use a breather connection on the carburettor although this is not nearly so sophisticated. The Smiths PCV valve is designed to provide a constant small vacuum regardless of what the engine is doing (whether idling or struggling up a hill where the engine vacuum is drastically different) but this is not the case with a breather type carburettor where the vacuum varies hugely.

So in terms of the "bees knees" of crankcase ventilation, as far as the factory standard Morris Minors were concerned, the latest version was an oil separator on the tappet chest and a breather type HS2 carburettor but the most sophisticated was a Smiths PCV valve.

- IMG_9374.jpeg (2.78 MiB) Viewed 3996 times

- IMG_9789.jpeg (4.46 MiB) Viewed 3996 times

- IMG_9788.jpeg (2.86 MiB) Viewed 3996 times

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 6:52 am

by mowogg

I run the PCV valve set up on my van and on one point quite a worn engine. It seems to me that under certain conditions this system does not keep up with production of gases in the engine, hence the need for a vented cap. I have no actual measurement of this, but you get an occasional smell of the gases. I would expect under these conditions a non vented cap would push oil out through the scroll

I have also tried the later set up with the vent to the carb on the same tired engine. This seemed to be worse and pushed oil out through the scroll . The PCV set up in my experience used less oil.

The PCV valve is not a fix for a tired engine.

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 8:18 am

by svenedin

Agreed. No breather set up can keep up with the crankcase compression of a very worn engine. The closed-circuit type breather systems should have a VENTED oil filler cap (see workshop manual which clearly explains this). This is deliberately restricted but is an inlet for fresh air. Engines that originally had closed circuit breathing are prefix 10ME not the usual 10MA.

Stephen

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 8:19 am

by Mr. V

Thanks for your replies but I think you're all missing my point.

I was theorising that, if one purpose of maintaining negative crankcase pressure (by means of a manifold/carb tapping) is to ensure that the crankshaft scroll is able to do its job, then would not having an unvented oil filler cap cause more air to be drawn in through the scroll, helping it further?

That is why I then went on to worry about even more clutch dust being drawn in with that air, and suggesting that the ideal solution would be a lip seal on the rear of the crankshaft, with all the hassle and expense that that would involve (dismantling, machining etc.).

It was more an academic exercise than anything else.

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 8:36 am

by mowogg

I think it would 95% of the time yes. But 5% of the time it would push more oil out through the acroll when the system over presurises

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 9:41 am

by geoberni

Mr. V wrote: ↑Sat Sep 14, 2024 8:19 am

Thanks for your replies but I think you're all missing my point.

Actually I think you're the one missing the point.

Considering the many hours of engine running, the idea that there could be a benefit to having such a reduced pressure inside the engine that it would pull 'clutch dust' back past the scroll is IMHO, quite amusing.

At best, it might simply make the clutch dust stick to the lip of the seal.

The total amount of dust from new to needing replacement, is probably about an egg cup full; even supposing it could be pulled in via the scroll, how many oil changes would have taken place in that time??

IMHO, your basic proposition just does not pass scrutiny ....

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 10:14 am

by Mr. V

I'm glad you're amused.

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 12:04 pm

by svenedin

Mr. V wrote: ↑Sat Sep 14, 2024 8:19 am

Thanks for your replies but I think you're all missing my point.

I was theorising that, if one purpose of maintaining negative crankcase pressure (by means of a manifold/carb tapping) is to ensure that the crankshaft scroll is able to do its job, then would not having an unvented oil filler cap cause more air to be drawn in through the scroll, helping it further?

That is why I then went on to worry about even more clutch dust being drawn in with that air, and suggesting that the ideal solution would be a lip seal on the rear of the crankshaft, with all the hassle and expense that that would involve (dismantling, machining etc.).

It was more an academic exercise than anything else.

This has been discussed at length before even to the point of measuring the partial vacuum in inches of water. Yes, with closed circuit breather an unvented filler cap increases the partial vacuum but at the risk of excessive oil being sucked into the engine and burnt. The vented cap is deliberately designed to be restrictive so that a small partial vacuum is maintained.

Stephen

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 12:34 pm

by philthehill

I would suggest that if your engine is causing concern as regards its polluting qualities then it is time to overhaul your engine.

The PCV and other valves fitted to the 'A' Series engines were not fitted as a result of the engine being unsound but because of legislation imposed upon it.

A well built 'A' Series engine does not need a PCV or other valve to function correctly and still be within the required pollution control restraints.

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 5:01 pm

by Mr. V

Thanks for that interesting point Stephen, and as I said Phil, I was just enquiring out of no more than academic interest. My engine is, I hope, in rudish health, apart from carburation, but that is a matter for another thread in which I will look forward to your no doubt insightful and interesting (and no doubt disappointing, due to the assembly of unmatching parts that is my engine) comments.

Until then.

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 6:01 pm

by les

The Manifold I’ve found with the PCV fitting is 12G 1514. I intend to clean it up and fit it, to see if it’s an improvement.

- IMG_1892.jpeg (3.1 MiB) Viewed 3829 times

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 6:06 pm

by philthehill

It has to be remembered that these posts are not only read by the OP but others to gather information. Therefore posts may have a related but slightly wider scope/interest than just a direct answer to the OPs question.

Phil

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 8:27 pm

by BaritoneUke

this was an interesting one featuring breathing - 1st prize for sophistication?

MMT1968

Minor Friendly

Posts: 69

Joined: Fri Dec 22, 2023 8:20 pm

Location: Germany

MMOC Member: No

Contact: Contact MMT1968

Re: Crank rear oil seal

Post by MMT1968 » Fri Aug 16, 2024 7:35 pm

As many others I had the same problem to solve anyhow. But as my returning scroll on the crank shaft was badly worn and the parts of the block around it also I decided to use a lip seal conversion kit. …. And got the problems as predicted. At last I had to pull the engine out 8 times due to partly massive oil leaks. But now it is solved, not a single drop of oil is leaking out of the rear crank seal. And that’s not because there is no oil inside the engine.

My engine is a 1275 marina and the kit therefore is different from the others for smaller ones. The screws holding the seal housing to the block must pass outside the crank shaft flange which needs three recesses in the inner wall of the seal housing. These are very difficult to get sealed well at that point. I glued the lip seal in at last and filled these recesses with motor silicone. I also mounted a speedy sleeve and must say I‘m convinced it will never work without.

But! It will never work without a good or better perfect crank case ventilation system. I have tried all published versions but none did it’s job well enough. So I ended with the installation of an electric vacuum pump. That works perfectly. The amount of vakuum put on the crank case is easily adjustable and the ventilation hose is lead into an oil catch can. If the vacuum is adjusted correctly that catch can is completely dry.

Phil called it a bit of an overkill. Anyway, it works, so it’s fine.

So, if the original returning scroll is in a useful shape try to keep it and live with a few drops of oil under the car. That’s easier than having to face all the problems with a lip seal conversion kit.

After all this training I can pull the engine out in 1 hour now and putting it back in needs just 90 minutes.

Good enough for an amateur.

Chris

Last edited by MMT1968 on Sat Aug 17, 2024 9:52 am, edited 1 time in total.

Re: Crankcase Breathing

Posted: Sat Sep 14, 2024 8:34 pm

by philthehill

I still consider it an overkill reaction to a non problem that a well built engine will not succumb to.

Re: Crankcase Breathing

Posted: Mon Sep 16, 2024 10:23 pm

by les

My oil leak is now minimal, and as I’ve mentioned I intend to fit a manifold that allows the fitting of a PCV valve hoping it will be better than the canister to carb system I have now. —————in view of reading these posts, I’m wondering if I’m wasting my time by doing this swap ?

Re: Crankcase Breathing

Posted: Mon Sep 16, 2024 10:50 pm

by BaritoneUke

It's a bit of an experiment really...with quite a high chance of there being no further improvement - after all it's an emissions improvement system. Wouldn't bother myself.