Page 1 of 1

Distributor drive 180 out

Posted: Wed Aug 07, 2024 3:43 pm

by morris63

I have just rebuilt my Engine, and I think I may have the Distributor drive 180 out.. Does this matter? Can I still set the timing? When no1 cylinder in at TDC on compression the rotor arm points down,(Between7 and 8 on a clock face) so as long as the lead from there goes to No1 plug it should run??

Re: Distributor drive 180 out

Posted: Wed Aug 07, 2024 5:42 pm

by geoberni

If it's 180 Out I'd assume it will point the Vacuum advance in a strange direction

Re: Distributor drive 180 out

Posted: Wed Aug 07, 2024 5:54 pm

by paul 300358

If its 180 deg out fit as usual and plug the leads in on the opposite side of the cap

Re: Distributor drive 180 out

Posted: Thu Aug 08, 2024 12:15 am

by exlkrs

geoberni wrote: ↑Wed Aug 07, 2024 5:42 pm

If it's 180 Out I'd assume it will point the Vacuum advance in a strange direction

No, only the rotor would be 180 out, the body would be in the same position. Hence you can change the leads round to suit and use the timing marks as normal.

Re: Distributor drive 180 out

Posted: Thu Aug 08, 2024 5:41 am

by Sleeper

... or you could remove the dissy, remove the dissy-driveshaft, rotate 180 and refit in15 minutes.. ( magnet on a stick helps)

John ;-)

Re: Distributor drive 180 out

Posted: Thu Aug 08, 2024 10:49 am

by olonas

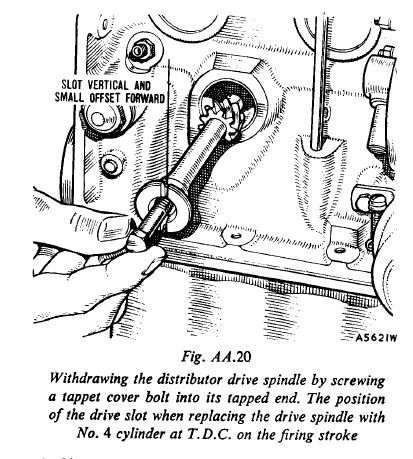

I would use a long enough bolt into the end of the shaft rather than risk a magnet. 5/16" UNF.

There should be videos on the YTube showing how to install it with the correct orientation.

This might help.

https://www.youtube.com/watch?v=gs3pNASKiBc

Re: Distributor drive 180 out

Posted: Thu Aug 08, 2024 11:46 am

by geoberni

olonas wrote: ↑Thu Aug 08, 2024 10:49 am

I would use a long enough bolt into the end of the shaft rather than risk a magnet. 5/16" UNF.

There should be videos on the YTube showing how to install it with the correct orientation.

This might help.

https://www.youtube.com/watch?v=gs3pNASKiBc

Sleeper wrote: ↑Thu Aug 08, 2024 5:41 am

... or you could remove the dissy, remove the dissy-driveshaft, rotate 180 and refit in15 minutes.. ( magnet on a stick helps)

John ;-)

Or just use a Tappet Cover Bolt as described in the WS Manual....

- Dissy drive.JPG (65.76 KiB) Viewed 7674 times

Re: Distributor drive 180 out

Posted: Thu Aug 08, 2024 3:39 pm

by exlkrs

No need. Set at TDC No1, (both tappets rocking) then rotate distributor rotor so it point towards no 1 ( about ten past as you look at it), Insert distributor, move rotor until you feel the key click in the slot, push home fully, then time properly.

Re: Distributor drive 180 out

Posted: Fri Aug 09, 2024 8:03 am

by Sleeper

"" No need. Set at TDC No1, (both tappets rocking) then rotate distributor rotor so it point towards no 1 ( about ten past as you look at it), Insert distributor, move rotor until you feel the key click in the slot, push home fully, then time properly. ""

Is this correct? I thought the slot/key was " offset" , so one the dissy could only be inserted "one way " ?

John ;-)

Re: Distributor drive 180 out

Posted: Fri Aug 09, 2024 8:30 am

by philthehill

Only the drive shaft (driven from the camshaft) has an offset slot. The distributer shaft has an offset protrusion/key which matches and fits into the drive shaft slot.

In reality - the drive shaft can be fitted in any position and the distributer (but not in practice) turned to any position within 360 degrees. It can still be timed to suit No: 1 cylinder approaching TDC on compression by fitting the plug leads to suit.

Using the workshop manual instructions and diagram is best for setting the timing.

Re: Distributor drive 180 out

Posted: Fri Aug 09, 2024 11:05 am

by exlkrs

Sleeper wrote: ↑Fri Aug 09, 2024 8:03 am

"" No need. Set at TDC No1, (both tappets rocking) then rotate distributor rotor so it point towards no 1 ( about ten past as you look at it), Insert distributor, move rotor until you feel the key click in the slot, push home fully, then time properly. ""

Is this correct? I thought the slot/key was " offset" , so one the dissy could only be inserted "one way " ?

John ;-)

Never found one that didn't!!

- diz.jpg (303.34 KiB) Viewed 7582 times

Re: Distributor drive 180 out

Posted: Sat Aug 10, 2024 7:45 am

by Sleeper

Maybe the ( thinner?) offset key fits in the ( wider? ) offset slot either way ?

John ;-)

Re: Distributor drive 180 out

Posted: Sat Aug 10, 2024 8:31 am

by exlkrs

Sleeper wrote: ↑Sat Aug 10, 2024 7:45 am

Maybe the ( thinner?) offset key fits in the ( wider? ) offset slot either way ?

John ;-)

As I said, never found one that didn't.

Re: Distributor drive 180 out

Posted: Sun Aug 11, 2024 9:26 am

by Andmurph

They are often offset. Be careful and don’t force it as it can cause damage and a later breakdown.

This one on my 1275 was forced in at some stage and caused the casting to crack. It takes 10 - 15 minutes to turn the drive dog or less to rearrange the HT leads.

Re: Distributor drive 180 out

Posted: Thu Aug 15, 2024 8:42 am

by morris63

To rape things up.

Thank you for all your replys. I left the drive 180 out and just rearranged the leads. All seems to work fine. So it does not matter if the drive is 180 out just set TDC to no 1 firing, see where the rotor arm is pointing and that is no 1 lead.

Re: Distributor drive 180 out

Posted: Thu Aug 15, 2024 9:32 am

by svenedin

The distributor drive dog IS offset and will only fit properly one way but it is hard to see in a photo. If inserted 180 degrees out the distributor will go "almost" fully home against the block but there will be a gap. When inserted correctly the distributor goes absolutely flush against the block.

Stephen

- IMG_8874.jpeg (501.21 KiB) Viewed 7362 times

Re: Distributor drive 180 out

Posted: Thu Aug 15, 2024 10:24 am

by les

This is like defending the indefensible. Is it such a big deal to get it right

Re: Distributor drive 180 out

Posted: Thu Aug 15, 2024 11:00 am

by Bill_qaz

The illustration posted from the manual clearly shows the distributor drive position, and states with the engine firing on number 4. Its similar to the discussion had that when the crank and cam timing marks are aligned the engine is also firing on number 4. The ignition timing is a different action and the references are number 1 firing.using external timing mark.

If you are happy doing it differently then so be it,it's your car