Page 1 of 1

How does this sound

Posted: Wed Aug 24, 2022 8:33 pm

by dudload

Not sure if I'm now getting to minute details, but after changing the head, replacing bearing shells, with a new carb (butterfly bearings badly worn on old one) I still think this is a bit noisy.

Annoyed I didn't change rocker assembly during the head change - sound a bit tappety?

https://youtu.be/8b6fkWeETrE

Re: How does this sound

Posted: Wed Aug 24, 2022 9:39 pm

by philthehill

I am sorry to say that I have to agree with you in that the engine is very noisy.

Re: How does this sound

Posted: Wed Aug 24, 2022 9:43 pm

by dudload

As I thought really, what do you think the noise is mainly? Worth just biting the bullet and changing rocker assembly - if so, is that a new head gasket or take the risk?

Re: How does this sound

Posted: Wed Aug 24, 2022 10:09 pm

by philthehill

I suspect the rocker assy. Did you fit new cam followers?

You can replace the rockers and shaft without having to disturb the head if you can disengage the rocker shaft locking peg from the plate that goes under the 3/8" head nut and 5/16" rocker pedestal nut and which holds the locking peg in place. For future reference cut the locking plate so that the locking plate is held by the 5/16" pedestal nut only. BL did this but the other way around the reduced locking plate was held by the 3/8" head stud.

If you can overcome the locking plate issue - slacken and back right off the adjuster screws and pull the rockers to one side. Remove the push rods. Remove the rocker shaft locking peg and split pins. Slide the rocker shaft forward disengaging the rockers and springs and washers. Reassemble in the reverse order.

It is worth the risk of having to remove the 3/8" head nut holding the rocker shaft locating peg plate in place especially if the locking peg has been moved to No: 2 pedestal. Modify the plate before refitting the plate.

Anyone who is removing a 'A' Series head should modify the locking plate before assembly as it allows for the future removal of the rockers and shaft without having to disturb the head.

Good luck

Re: How does this sound

Posted: Thu Aug 25, 2022 1:21 am

by dudload

Thanks Phil,

No, the cam followers weren't replaced at the time as they were out of stock on esm I seem to recall. There was some slight putting, so perhaps worth reaching them via the tappet chest?

I'll probably just buy a new whole rocker assembly to avoid the risk of the bearings and shaft being worn. Does that make a difference to disassembly procedure?

If I read correctly, are you saying that if I can't get around the plate removal, it's worth risking slacking that one head nut fully off to remove?

Re: How does this sound

Posted: Thu Aug 25, 2022 6:51 am

by oliver90owner

Are you sure you didn’t set the clearances to metric sizes, but using imperial feelers?

Exactly how did you set the clearances? First action might be to check they are actually as per specification.

Did you adjust the tappets without checking if the surfaces were deeply worn/grooved? Sounds like a bag of beans.

If your main bearing replacements are on a similar level of precision, that engine will not last long before it needs further attention.

Is there any alternative to slacking that nut if you are going to take the risk? Your choice.

Do you have any precision measuring equipment, beyond feeler gauges?

Re: How does this sound

Posted: Thu Aug 25, 2022 8:08 am

by philthehill

I would replace those cam followers, even the slightest pitting soon turns to pocketing.

If you replace the whole rocker assy including pedestals then you will need to replace the head gasket as you will undoing 40% of the head studs.

The shaft is the first to wear, the bearings in the rockers hardly ever wear. The hammer head of the rocker gets pitted and the case hardening of the tip gets worn through. The hammer head can be re-profiled but the case hardening gets very thin and soon wears out.

It is worth the risk of removing the one head nut (with the engine cold and the block drained of coolant) to enable the locking plate for the rocker shaft peg to be removed but personally I would remove the rocker assy, head and replace the head gasket, rocker assy and cam followers in one hit.

Make sure that you modify the rocker shaft locking plate upon reassembly.

Re: How does this sound

Posted: Thu Aug 25, 2022 1:52 pm

by dudload

oliver90owner wrote: ↑Thu Aug 25, 2022 6:51 am

Are you sure you didn’t set the clearances to metric sizes, but using imperial feelers?

Exactly how did you set the clearances? First action might be to check they are actually as per specification.

Did you adjust the tappets without checking if the surfaces were deeply worn/grooved? Sounds like a bag of beans.

If your main bearing replacements are on a similar level of precision, that engine will not last long before it needs further attention.

Is there any alternative to slacking that nut if you are going to take the risk? Your choice.

Do you have any precision measuring equipment, beyond feeler gauges?

For the bearing shells, i used a micrometer and plastiguage to check the clearances which were all withing spec and no scoring on the centre main (couldnt change rear and front as did it engine in)

Now, for the clearances, I did set them myself but took the car to LMG kent for a bit of welding on the chassis leg. Asked them to have a look at the engine, they said it was ok but that they changed the clearances - I'm now doubting if they have used the wrong numbers (if you want it done properly, do it yourself).

The car was a bit quieter when i'd done the clearances, but probably still a bit noisy. I'll do it myself and repost another video. Don't have the energy to take the head back off again, will probably leave to early next year.

btw. when removing the head, is there enough space/give in exhaust to undo the manifold bolts and pull it to one side (suitably supported) whilst working on the head? The main hassle of the head was doing exhaust seal etc.

Re: How does this sound

Posted: Thu Aug 25, 2022 2:12 pm

by myoldjalopy

Yes, you can just pull the manifold and tie it to one side, but you may find the exhaust pipe seal gets compromised in the process......

Re: How does this sound

Posted: Thu Aug 25, 2022 5:03 pm

by les

They’re not digging the road up near you are they ? —————— Sorry, —-the devil made me do it !

Re: How does this sound

Posted: Thu Aug 25, 2022 7:40 pm

by King Kenny

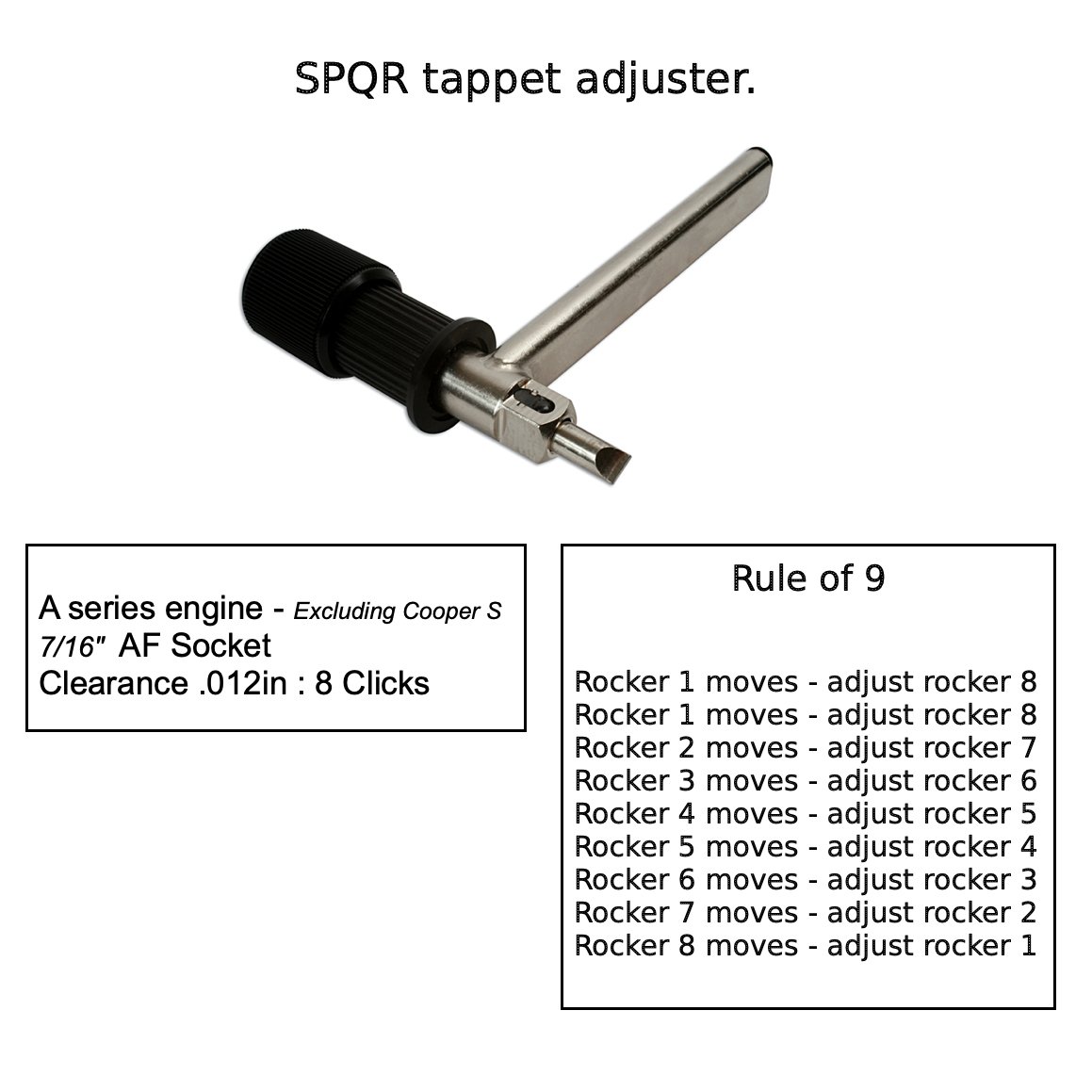

I have never used feeler gauges as the are difficult to get a correct gap. I use an SPQR (Gunson) adjuster. 8 clicks and it's done.

- qw.jpg (138.54 KiB) Viewed 1176 times

Re: How does this sound

Posted: Thu Aug 25, 2022 8:44 pm

by philthehill

Make sure that you have the correct special SPQR socket (not shown in the photo above) 1/2" drive x 7/16" AF.

If you do not have the special SPQR socket you can adapt a 1/2" drive 7/16" UNF socket to suit. Requires a hole drilling for the socket retaining plunger otherwise the socket can drop off the end of the adjuster at the most inopportune moment .

Most SPQR tappet adjusters seem to be supplied with the 1/2" drive 1/2" UNF socket.

https://www.ebay.co.uk/itm/185547239037 ... R-S43-jaYA