Page 1 of 2

Tappety tappets

Posted: Sun Dec 12, 2021 5:21 pm

by Grumpy21

Trying to get to the bottom of my inability to stop the tappets from being so noisy.

Worn components!

Bottom of the rocker shaft is very worn and three of the rockers are worn there they contact the valves

replacement required I think but will mine be OK as exchange?

Re: Tappety tappets

Posted: Sun Dec 12, 2021 5:27 pm

by jagnut66

Re: Tappety tappets

Posted: Sun Dec 12, 2021 5:46 pm

by Grumpy21

sorry Mike, wrong end of the stick.

The shaft itself is worn, estimate up to 1mm in places and some of the rockers at the valve end are worn too 0.4mm ish

I'd need a new shaft and at least 3 but probably 6 rockers, a replacement recon assembly is more economical if they will accept mine in exchange

Re: Tappety tappets

Posted: Mon Dec 13, 2021 1:00 am

by jagnut66

If I now understand you correctly I've found you two options, the first is from a 998 Mini engine but I believe they are the same as ours.

It looks to be in very good condition:

https://www.googleadservices.com/pagead ... IAQ&adurl=

The second is the reconditioned route, which is more expensive:

https://www.morrisminorspares.com/engin ... ge-p830261

Best wishes,

Mike.

Re: Tappety tappets

Posted: Mon Dec 13, 2021 8:42 am

by Grumpy21

Hi Mike

I'd prefer the reconditioned route but currently unavailable at the price your link shows - yet the same item is available at £135!

Theres loads on ebay for anything between £15 and £35 but they could be as bad as mine! (which is very bad now I've stripped it.

Two observations though, I'm wondering if I could turn the shaft upside down and re-use it for a little while (it would need the locating hole re drilling with might be interesting. Also every used one I can see has circular wear on valves 1 and 8 (as does mine) from contact with the valve stem. this obviously make setting the tappet gap almost impossible.

Gary

Re: Tappety tappets

Posted: Mon Dec 13, 2021 9:32 am

by philthehill

You cannot turn the shaft upside down as the shaft is pegged in place and I certainly would not consider drilling the shaft to suit the peg.

The locating peg was moved to pillar No: 2 as there were already too many holes in the shaft causing the shaft to fail at pillar No: 1. More holes in the shaft increases the likelihood of shaft failure.

If the shaft is worn replace it! I would replace the shaft with the heavy duty type.

It is unusual for the rocker bushes to be worn - the shaft wears out first.

It is not recommended that the pressed steel rocker bushes are replaced as the process can distort the rocker body.

The tip of the rocker in contact with the valve stem is hardened and once the hardness is worn through the wear accelerates. beware of reconditioned rockers where the tip has been reprofiled as the hardening may be non existent.

I would not recommend the use of alloy rocker shaft pillars as they get squeezed and subsequently the studs lose their grip/torque. Use the sculptured steel pillars and then the pillars can be machined to centralise the rocker over the top of the valve.

As regards setting the valve clearance - the SPQR valve adjuster is ideal for setting the clearance with worn rockers.

Re: Tappety tappets

Posted: Mon Dec 13, 2021 1:21 pm

by Grumpy21

Bought a decent replacement via eBay but couldn’t resist seeing if I could turn the shaft over.

All done and it now runs nice and quietly. Replacement will turn up this week and I’ll fit that instead.

I do like a fiddle

Re: Tappety tappets

Posted: Mon Dec 13, 2021 4:53 pm

by JOWETTJAVELIN

Check oil delivery whilst you’re at it.

Re: Tappety tappets

Posted: Mon Dec 13, 2021 7:23 pm

by philthehill

As regards oil transfer between the rocker shaft pillar and the original rocker shaft you should be ok as there are two oil transfer holes. One at 180 degrees to the locating peg and the other is the locating peg hole itself when the shaft is turned. So you can turn the rocker shaft upside down but as I said above drilling the extra hole for the peg is seriously weakening the rocker shaft to the point that the shaft may fail.

If your locating peg is in No: 2 pillar the oil transfer hole is drilled right through the shaft at No: 1 pillar so no problems turning the shaft upside down.

Re: Tappety tappets

Posted: Mon Dec 13, 2021 9:08 pm

by Grumpy21

as stated above I've done it and it runs fine with considerable less tappet chatter. Sort of proof of concept. Ive also bought what seems to be a good replacement with minimal wear evident which I will fit as soon as it arrives. I'm unlikely to many if any miles until then so I don't foresee a reliability issue - unless it fails immediately, which it didn't.

Re: Tappety tappets

Posted: Wed Dec 15, 2021 2:21 pm

by King Kenny

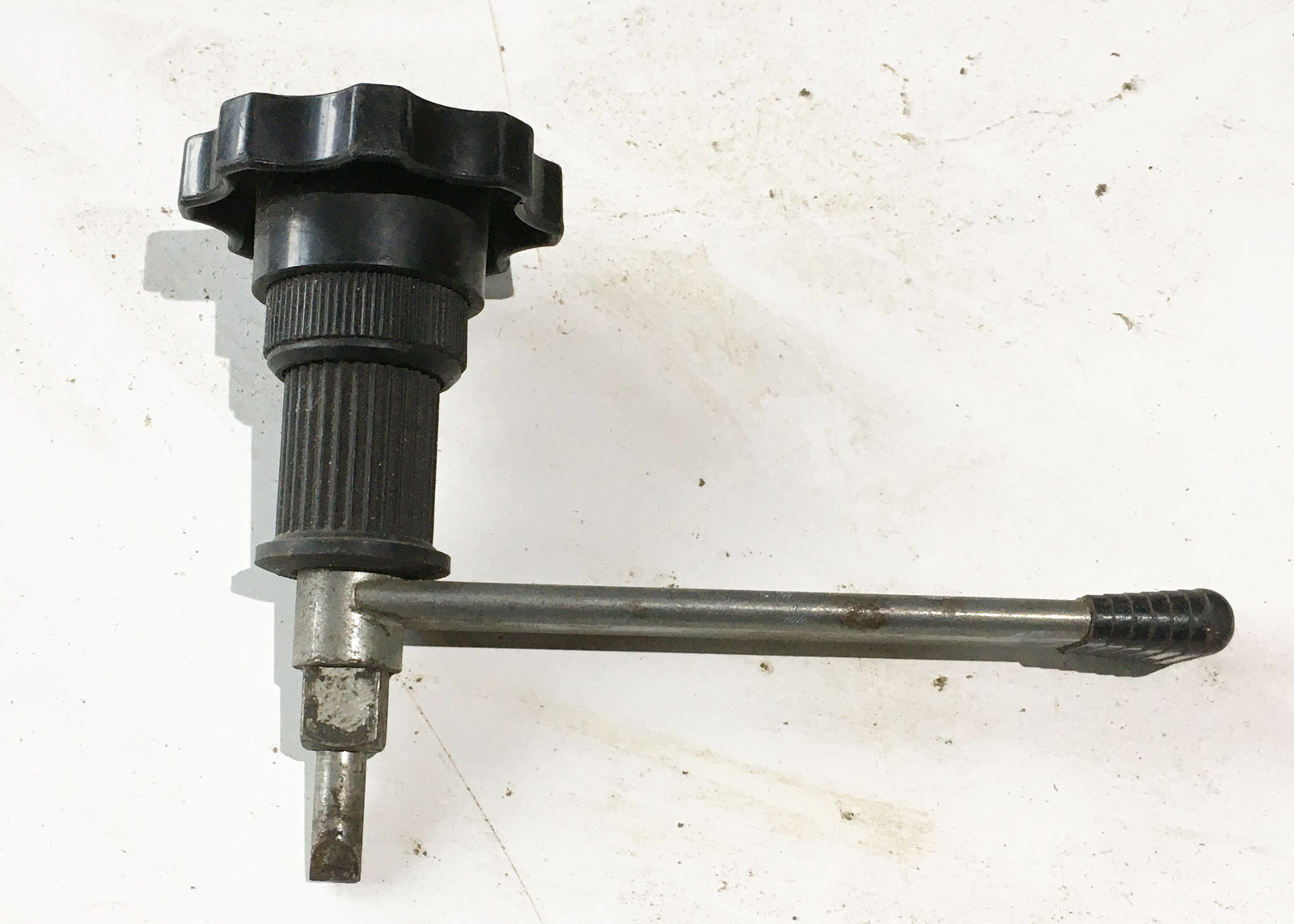

Getting the correct tappet gap is a bit of an art. Many years ago I bought a SPQR Tappet Adjuster. With 8 clicks I have the correct gap regardless of wear.

- IMG_0560web.jpg (173.87 KiB) Viewed 1925 times

Re: Tappety tappets

Posted: Wed Dec 15, 2021 5:33 pm

by oliver90owner

King Kenny wrote: ↑Wed Dec 15, 2021 2:21 pm

Getting the correct tappet gap is a bit of an art. Many years ago I bought a SPQR Tappet Adjuster. With 8 clicks I have the correct gap regardless of wear.IMG_0560web.jpg

Is that with no feeler gauges involved?

Re: Tappety tappets

Posted: Wed Dec 15, 2021 6:51 pm

by philthehill

You do not need feeler gauges when using the SPQR rocker clearances.

Re: Tappety tappets

Posted: Wed Dec 15, 2021 7:32 pm

by oliver90owner

Thanks Phil. It means that any wear on the rocker pad faces is taken into account - often a problem, with those that use feeler gauges between valve stem and worn surfaces, leading to excessive clearances being set.

Re: Tappety tappets

Posted: Fri Dec 17, 2021 2:08 pm

by myoldjalopy

So can anyone hazard a guess as to how many thousands of miles before one of these tools is worth using due to wear on the rocker faces?

Re: Tappety tappets

Posted: Fri Dec 17, 2021 4:27 pm

by philthehill

Examine the rocker anvil faces and if there is any sign of wear the SPQR tappet adjuster will be well worth the money.

You do not have to remove the rocker to check the wear. Just undo the adjustment nut right off, slip out the push rod (making sure that you do not lift the cam follower out of the block) push the rocker to one side, rotate and see the wear.

Re: Tappety tappets

Posted: Fri Dec 17, 2021 5:18 pm

by Grumpy21

myoldjalopy wrote: ↑Fri Dec 17, 2021 2:08 pm

So can anyone hazard a guess as to how many thousands of miles before one of these tools is worth using due to wear on the rocker faces?

Just once.

Even with the ‘upside down’ rocker shaft there was still some tappet chatter due to wear on the rocker faces.

Replacement shaft and adjustment with the spqr tool and I now have the quietest A series I’ve ever owned (and that must be well into double figures)

Cheers all

Gary

Re: Tappety tappets

Posted: Sat Dec 18, 2021 11:12 am

by myoldjalopy

philthehill wrote: ↑Fri Dec 17, 2021 4:27 pm

Examine the rocker anvil faces and if there is any sign of wear the SPQR tappet adjuster will be well worth the money.

You do not have to remove the rocker to check the wear. Just undo the adjustment nut right off, slip out the push rod (making sure that you do not lift the cam follower out of the block) push the rocker to one side, rotate and see the wear.

That is useful, practical advice, Phil, but it doesn't really answer my question about mileage - can you or anyone else hazard a guess?

Re: Tappety tappets

Posted: Sat Dec 18, 2021 11:37 am

by philthehill

How long is a piece of string...............!

A well maintained engine could give 60,000 plus miles and a badly maintained engine could give as little as 20,000 miles.

Re: Tappety tappets

Posted: Sat Dec 18, 2021 11:44 am

by Grumpy21

myoldjalopy wrote: ↑Sat Dec 18, 2021 11:12 am

philthehill wrote: ↑Fri Dec 17, 2021 4:27 pm

Examine the rocker anvil faces and if there is any sign of wear the SPQR tappet adjuster will be well worth the money.

You do not have to remove the rocker to check the wear. Just undo the adjustment nut right off, slip out the push rod (making sure that you do not lift the cam follower out of the block) push the rocker to one side, rotate and see the wear.

That is useful, practical advice, Phil, but it doesn't really answer my question about mileage - can you or anyone else hazard a guess?

As above but with adjust criteria. Zero miles and in profit!

Reasoning; worn rocker shaft and 5 worn rockers. No amount of adjusting with feeler gauges could account for the wear in the rocker faces. One spqr tool at £13 delivered compared to £60 on new rockers and I’m £47 ahead without going anywhere.