Page 1 of 2

fitting layshaft

Posted: Wed Jul 14, 2021 7:37 pm

by Woodyalan

Hi

Reassembling my gearbox having fitted new bearings. Am trying to fit new layshaft. Clearly gearwheels and laygears must be brought into mesh for the layshaft to be inserted but I'm finding this impossible. If there was no 3rd motion shaft fitted or it was fitted with just first gear the layhaft would go in no trouble but with mainshaft fully fitted it's as if the gearwheels are pushing each other apart I ground down an old layshaft so I could temporarily fit that, tapered end first, then follow with the new shaft but it doesn't help as it will only go in so far before getting jammed in the laygear I've also used a cable tie round the laygear so as to lift it into position but no amount of jiggling will line things up. When looking at either end of the laygear the roller bearings should obviously be central but they are always offset and I can't see a way to correct it. Any ideas would be welcome as mine have run out.

Alan

Re: fitting layshaft

Posted: Wed Jul 14, 2021 9:30 pm

by philthehill

What gearbox have you?

Have you got the right layshaft?

What is the part number of the new layshaft?

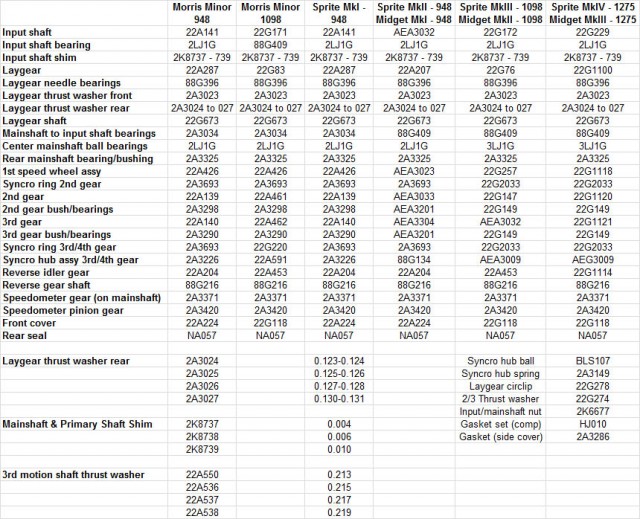

See the details in the attached list below for correct layshaft & part number:-

- gearbox data 1.jpg (132.31 KiB) Viewed 3131 times

Re: fitting layshaft

Posted: Wed Jul 14, 2021 11:27 pm

by Woodyalan

I don't know about part numbers but all the parts I have, new or used, are for standard 1098 Minor gearboxes. The layshaft is part of an overhaul kit supplied by Heathrow Transmissions including all bearings.

Alan

Re: fitting layshaft

Posted: Thu Jul 15, 2021 7:23 am

by philthehill

You do need to know the part numbers and make sure that you have the right part against the right part number or you could be for ever trying to make the layshaft fit.

The layshaft part number you require for a 1098cc gearbox is 22G83. Nothing else will fit.

Re: fitting layshaft

Posted: Thu Jul 15, 2021 10:18 am

by Woodyalan

Hi Phil

I understand what you say but the problem is not the layshaft itself. If you imagine you are looking at an assembled box that just needs the layshaft fitted then the roller bearings at each end of the laygear must be centralised or there is no possibility of inserting the layshaft and that is what I can't achieve. I have tried substituting other gearwheels but it it always turns out that the roller bearings are slightly offset and no amount of jiggling will centralise them. There must be something that causes the gearwheels and laygear not to mesh together properly thereby causing the laygear to be out of line.

Alan

Re: fitting layshaft

Posted: Thu Jul 15, 2021 10:23 am

by philthehill

Have you tried the old layshaft?

If the only thing/gears you have replaced is the layshaft and you now cannot mesh the layshaft with the first and third motion shafts which does not allow the bearings to line up with the shaft holes in the casing then the problem must lie with the layshaft.

Have you considered that someone may have fitted different gears to the gearbox - do you know the gearbox history?

Re: fitting layshaft

Posted: Thu Jul 15, 2021 12:03 pm

by Woodyalan

I don't know the history of the box , only that it was noisy, so I hoped new bearings would cure it. It is not possible to fit the new layshaft, which is the same as the old one, as the holes where it is inserted cannot be lined up with the roller bearings.

Re: fitting layshaft

Posted: Thu Jul 15, 2021 12:44 pm

by les

There are A type and B type gears but unless any gears have been replaced and presumably the gearbox was once assembled and working, its difficult to blame that. Also difficult to find an answer without having the gearbox to look at. However If any of the gears have been replaced, I’d be checking them.

Re: fitting layshaft

Posted: Thu Jul 15, 2021 3:12 pm

by Woodyalan

Could there be a slight (very slight) difference in the laygear clusters? I had three sets of laygears and it's possible I may not have put the same set in that came out.

Re: fitting layshaft

Posted: Thu Jul 15, 2021 4:35 pm

by philthehill

There are five different lay gears for the 'A' Series gearbox - see list above.

Re: fitting layshaft

Posted: Thu Jul 15, 2021 5:32 pm

by les

Woodyalan wrote: ↑Thu Jul 15, 2021 3:12 pm

Could there be a slight (very slight) difference in the laygear clusters? I had three sets of laygears and it's possible I may not have put the same set in that came out.

Now you tell us !

Re: fitting layshaft

Posted: Thu Jul 15, 2021 8:28 pm

by Woodyalan

Sorry! I'm probably clutching at straws here anyway, I doubt if that will turn out to be the cause of the problem. All the laygears looked the same and they would all have come from Minors. It may be a few days before I can check it out further.

Re: fitting layshaft

Posted: Thu Jul 15, 2021 9:02 pm

by les

Worth a try though, there may be a difference. If not, it’s a mystery!

Re: fitting layshaft

Posted: Fri Jul 16, 2021 7:48 am

by oliver90owner

les wrote: ↑Thu Jul 15, 2021 5:32 pm

Woodyalan wrote: ↑Thu Jul 15, 2021 3:12 pm

Could there be a slight (very slight) difference in the laygear clusters? I had three sets of laygears and it's possible I may not have put the same set in that came out.

Now you tell us !

How often does this happen? Far too often, for sure.

Opening sentence from OP “

Reassembling my gearbox having fitted new bearings”.

Re: fitting layshaft

Posted: Fri Jul 16, 2021 9:54 am

by philthehill

All the lay gears look the same but they are different.

Re: fitting layshaft

Posted: Fri Jul 16, 2021 4:37 pm

by paul 300358

Re: fitting layshaft

Posted: Sat Jul 17, 2021 4:33 pm

by newagetraveller

As far as I can remember, first I fit the first motion shaft in the case. Then I put the laygear loosely in the case with a length of welding rod through the laygear. Then I fit the third motion shaft in the case. Then I replace the welding rod with a long thick phillips type screwdriver from the rear. Then I use the phillips screwdriver to adjust the position of the laygear until I can insert the lay shaft from the front using a mole wrench to hold the lay gear and twist it.

Re: fitting layshaft

Posted: Sat Jul 17, 2021 5:35 pm

by Woodyalan

Thats pretty much what I've been trying to do. Unfortunately when it comes to lifting the laygear into mesh the roller bearings inside the laygear are not lining up with the access holes for the layshft and no amount of fiddling will make them line up. Unless Phil is right and I have fitted the wrong laygear I can't see what is causing it. I believe the first motion shaft will have to come out to remove the laygear so I will be getting a press tool for the job. Last time I got a neighbour to press the first motion shaft in but I can't keep imposing on him, it will be a useful tool to have anyway. I should know in a couple of days where I stand with the laygear,

Re: fitting layshaft

Posted: Sun Jul 18, 2021 8:12 am

by philthehill

Here is a new lay gear (Pt No: 22G83) for a 1098cc gearbox which quotes the number of teeth on the lay gear.

Just count the teeth on your lay gear and compare with the numbers quoted in the link below.

You will then know whether you have the correct lay gear or not.

https://www.ebay.co.uk/itm/113867459347 ... %3A2334524

Re: fitting layshaft

Posted: Sun Jul 18, 2021 1:35 pm

by newagetraveller

If you take the third motion shaft out and keep the first motion shaft in place can you fit the laygear and lay shaft in the correct position?