Page 1 of 1

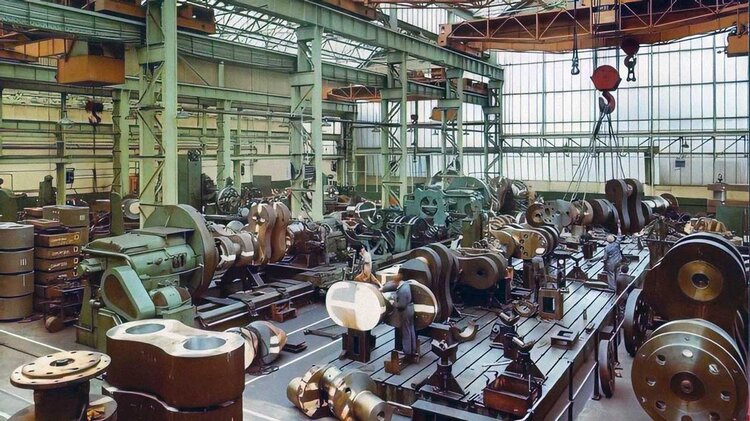

How’s this for a crankshaft?

Posted: Fri May 21, 2021 7:25 pm

by Mick Lynch

Doxford marine engine works, Sunderland - 1960

Re: How’s this for a crankshaft?

Posted: Fri May 21, 2021 7:34 pm

by Owlsman

How big are the big ends going to be for that? Surely they're going to need a box of giant ends?

I think they're still looking for some NOS.

Re: How’s this for a crankshaft?

Posted: Fri May 21, 2021 7:39 pm

by philthehill

And here is how a similar crankshaft is fitted without taking out the engine - marvellous

https://www.youtube.com/watch?v=2drej_qeRSA

https://www.youtube.com/watch?v=2drej_qeRSA

Re: How’s this for a crankshaft?

Posted: Fri May 21, 2021 8:15 pm

by Mick Lynch

Few more. Doxfords lasted until mid 80s. Building still stands.

- Doxford Pipe/repair shop 82

- 7DCCA7B8-F883-4E8C-92D2-B08A406DFE78.jpeg (170.63 KiB) Viewed 3540 times

I used to work up the Wear from there.

- Doxford Machine shop annex 60

- B64E64D6-0C57-41FD-81EA-0E5547F949B7.jpeg (131.16 KiB) Viewed 3540 times

Re: How’s this for a crankshaft?

Posted: Fri May 21, 2021 10:25 pm

by JOWETTJAVELIN

Interesting photos, thanks for posting. It wouldn't surprise me if those engines were still going strong, somewhere in the world.

Re: How’s this for a crankshaft?

Posted: Sat May 22, 2021 1:15 am

by irmscher

Ian Smithskids on the forum has worked on crankshafts a lot larger he may put some photos on

Re: How’s this for a crankshaft?

Posted: Sat May 22, 2021 6:33 am

by Propshaft

Brilliant photos , imagine having a drop off turning one of those cranks. ( drop off engineering term for mistake where you have to scrap the work peice)

Re: How’s this for a crankshaft?

Posted: Sat May 22, 2021 9:13 am

by philthehill

Re: How’s this for a crankshaft?

Posted: Sat May 22, 2021 11:44 am

by paul 300358

One of my jobs until I retired was eddy current testing the internal threads of the conrods off similar sized marine engines during refurb. I never found one that was cracked.

Re: How’s this for a crankshaft?

Posted: Sat May 22, 2021 3:18 pm

by philthehill

So - eddy's not only outside the ship but also inside the engine.

Re: How’s this for a crankshaft?

Posted: Sat May 22, 2021 6:31 pm

by paul 300358

philthehill wrote: ↑Sat May 22, 2021 3:18 pm

So - eddy's not only outside the ship but also inside the engine.

I never thought of that

Re: How’s this for a crankshaft?

Posted: Mon May 24, 2021 12:10 pm

by Mick Lynch

And this is when you have to take the full engine out

- EC0A21A9-B396-450B-BB99-B84F1BD8FF94.jpeg (402.98 KiB) Viewed 3355 times

- B91305E9-4C6D-45E2-8FAD-232F4B3E5D3F.jpeg (398.19 KiB) Viewed 3355 times

- DAFBC554-B0E3-45D7-A35A-EF0DE7C36B87.jpeg (218.78 KiB) Viewed 3355 times

Replacing the gensets on CCGS Cornwallis at out sister ship-repair yard via a ‘softpatch’ engineered into the ship when she was still on the drawing boards ’

Re: How’s this for a crankshaft?

Posted: Thu Aug 05, 2021 12:03 am

by brixtonmorris

Amazing. Can you imagine how they clocked the shaft with the dti.

They are using a 4 jaw chuck and a centre on the tail stock.

This looks good for the main bearings, but what kind of machine could machine the big end journals.

The offset is huge.

The face plate looks like it has the radius.

Whats going on with the tail stock?

Looking again, i don't think the 4 jaw is large enough.

It needs a larger diameter for the jaws to work.

It looks like the journal is very near to the diameter of the chuck.