Page 1 of 2

Rear Axle question

Posted: Tue Jul 03, 2018 12:52 pm

by geoberni

Hi all

So last weekend, had a fairly productive time sorting out basil, replacing a rusty Core Plug and tracing a small water drip from the water pump down to a loose clamp on the bypass hose.

Also took all wheels off and checked the brakes, including freeing up stuck cylinders on offside front.

What did puzzle me though was the rear axle.

Being a '55 series II, I was expecting to find an early set-up, i.e. section H in the manual, but instead found it has what the manual refers to as 'second type rear axle fitted to later models', so presumably it's had an axle change at some rebuild or another...

So, with that in mind, is it normal to have a bit of oil leakage when you take the rear wheel off?

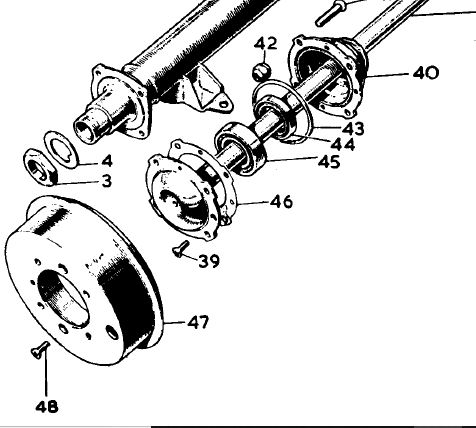

Seems to me that once the wheel is off, the cover plate only has one screw to hold it on (item 39), so if that isn't at the lowest point, it probably is going to have oil seep past the seal (46)....

- brake Rear.JPG (38.38 KiB) Viewed 3884 times

Am I right in thinking the axle's been replaced and that a drip is normal if the wheel is off and the screw is at the top?

Re: Rear Axle question

Posted: Tue Jul 03, 2018 1:44 pm

by jaekl

I always thought that most if not all Series II had the later axle. The wheel lugs compress the half shaft flange seals over time such that the screws may be loose. At the very least you should snug up the one flange screw before you remove the drum screws through the hole in the drum and give it another try after you replace the drum screws.

Re: Rear Axle question

Posted: Tue Jul 03, 2018 1:53 pm

by geoberni

Thanks jaekl

I thought the manual was a bit strange in that it didn't mention when the 'later models' ran from. No mention of 'Car Number XXXXX ' or similar like is often the case. I certainly didn't consider '55 to be 'later' in a production period that ran until the 70s!!!

Only had Basil since August last year and still working my way around. I think we've only done about 200 miles (can't be certain as one of the 1st jobs was to change the Speedo because the mileometer hadn't moved on for a few years!).

Re: Rear Axle question

Posted: Tue Jul 03, 2018 2:36 pm

by ManyMinors

It was indeed only the very early Series11s which had the "MM" type axle. A 1955 would have the "later type" - although it is not quite the same as those fitted to the 1098 cars.

Re: Rear Axle question

Posted: Tue Jul 03, 2018 3:03 pm

by ianmack

According to Ray Newell in Original Morris Minor the axle was changed in December 1953 from car number 228267.

Re: Rear Axle question

Posted: Tue Jul 03, 2018 3:55 pm

by philthehill

Over time the gasket (item No: 46 in the illustration above) between axle shaft and hub dries out and looses its ability to seal.

When fitting a new gasket smear the gasket with GP grease which will allow the gasket to remain supple for much longer.

To improve the sealing qualities of the hub gasket a rubber 'O' ring (item No: 43 in the illustration above) was introduced in addition to the gasket.

A worthwhile improvement is to fit the later hubs with rubber 'O' ring.

Re: Rear Axle question

Posted: Tue Jul 03, 2018 4:23 pm

by geoberni

Thanks all, very helpful as always.

Re: Rear Axle question

Posted: Tue Jul 03, 2018 8:28 pm

by alanworland

Must admit I didn't like the idea of one screw on the half shaft and as mine doesn't have an O ring I fitted another screw, which seems far more 'mechanical'

Alan

Re: Rear Axle question

Posted: Wed Jul 04, 2018 6:59 am

by philthehill

Whilst fitting a second screw may seem more mechanical - ultimately it is all held together by the wheel studs/nuts.

Re: Rear Axle question

Posted: Wed Jul 04, 2018 10:09 am

by alanworland

I realise that the wheel nuts hold it all together, I fitted the additional screw for the reason of securing the flanges together while the wheel was removed.

Alan

Re: Rear Axle question

Posted: Wed Jul 04, 2018 3:09 pm

by geoberni

alanworland wrote: ↑Wed Jul 04, 2018 10:09 am

I realise that the wheel nuts hold it all together, I fitted the additional screw for the reason of securing the flanges together while the wheel was removed.

Alan

As soon as I realised what was happening, I just rotated the shaft so that the screw was bottom most and that sorted it.

Re: Rear Axle question

Posted: Wed Jul 04, 2018 4:20 pm

by ampwhu

since fitting the later hub with the rubber ring seal and fitting my own made cork halfshaft 'gaskets' ive had no leaks for years.

Re: Rear Axle question

Posted: Wed Jul 04, 2018 5:51 pm

by philthehill

The thickness and strength of the gasket is important as it determines the fit of the bearing in hub.

A cork gasket is not the right material for this application.

The correct thickness gasket paper gasket must be used.

The cork gasket is squashable whereas the paper gasket retains its integrity as regards thickness and therefore is highly suitable for use as the half-shaft to hub gasket.

See BMC wksp Man Sect HH2 for details.

The use of a cork gasket may lead to the hub bearing not being clamped sufficiently in the hub so allowing the bearing to rotate in the hub leading to wear of the bearing seat.

There has been quite a lot of discussion (which can be found by using the search facility) on this forum as regards the hub to half-shaft gasket and especially its thickness in relation to holding the hub bearing in its correct orientation.

I would choose the correct thickness paper gasket over cork every time.

Phil

Re: Rear Axle question

Posted: Thu Jul 05, 2018 1:34 pm

by jaekl

The thickness of the gasket isn't as important as the material. It's all part of the sandwich that is clamped by the lugs. The bearing race stands proud of the hub and therefore is clamped. The gasket just add more thickness. However, the paper gasket against the relatively thin surface area of the outer race tends to breakdown. To overcome that they added the O-ring after a few years. The real debate is whether the gasket is even needed any more.

Re: Rear Axle question

Posted: Thu Jul 05, 2018 2:20 pm

by philthehill

jaeki

I would suggest that you do need to read the BMC wksp Manual section HH2 as the thickness of the gasket has a material effect on the clamping forces holding the bearing in the hub.

In section HH2 BMC give a specific bearing protrusion measurement which is taken from the outer face of the gasket when fitted to the hub.

Therefore the gasket does not just add thickness it is a specific part of measuring bearing protrusion so gasket thickness is important.

The paper gasket does not have any contact with the hub bearing outer race - it fits around the outer race of the bearing which is 71.7mm OD.

The internal dia of the gasket is 73mm.

The gasket is needed and should be the right thickness.

The bearing is gripped between the abutment shoulder in the hub and the driving flange of the axle shaft.

The 'O' ring was fitted to later cars to eliminate axle oil weeping when the gasket dries out.

Hence my recommendation that the gasket is lightly greased on assembly.

Phil

Re: Rear Axle question

Posted: Thu Jul 05, 2018 3:43 pm

by jaekl

Thanks for pointing that the gasket is on the outside of the bearing. I just did this job in the last few weeks, but I've done it so often, I'm not even looking at it so I forgot that the gasket sits outside the bearing. With the gasket not included in the bearing-flange clamp, BMC didn't have a chance keeping the joint dry. The gasket had to accommodate the tolerances of the hub and bearing. Its function is more like a shim or spacer. Of course a thicker gasket should never be used.

Re: Rear Axle question

Posted: Thu Jul 05, 2018 5:32 pm

by geoberni

Well, who'd have thought that my little question would reveal so much....

Thanks everyone.

Re: Rear Axle question

Posted: Thu Jul 05, 2018 6:00 pm

by ampwhu

for me, proof is in the pudding. I've had no problems/leaks for at least 10 years or even longer. I've made my own cork gaskets and used them pretty much all over the drivetrain. this also includes the diff gasket.

common issue of leaking was the timing case cover. that has a cork gasket and has never leaked either.

Re: Rear Axle question

Posted: Thu Jul 05, 2018 6:45 pm

by jaekl

ampwhu, the issue isn't leaking with your cork gasket of unknown thickness. It's bearing clamping effectiveness. The bearing press fit is so light some people report being able to push the hub in and out until they install and tight the half shaft. Possible your cork compressed enough to clamp the bearing but you may be just on the edge of allowing the bearing to squirm.

Re: Rear Axle question

Posted: Thu Jul 05, 2018 7:29 pm

by ampwhu

there isn't a problem with the bearings. they have been 'pressed' into the hub and don't move. no sure what others experience, but 'ive never had this issue. the cork used was similar thickness to the paper gaskets. I think this was a poor design. one thing to make sure, is that the drain hole in the axle casing is clear.