Page 1 of 1

Blocked water Ports

Posted: Sat Jun 23, 2018 4:34 pm

by fasthamster

Hi All,

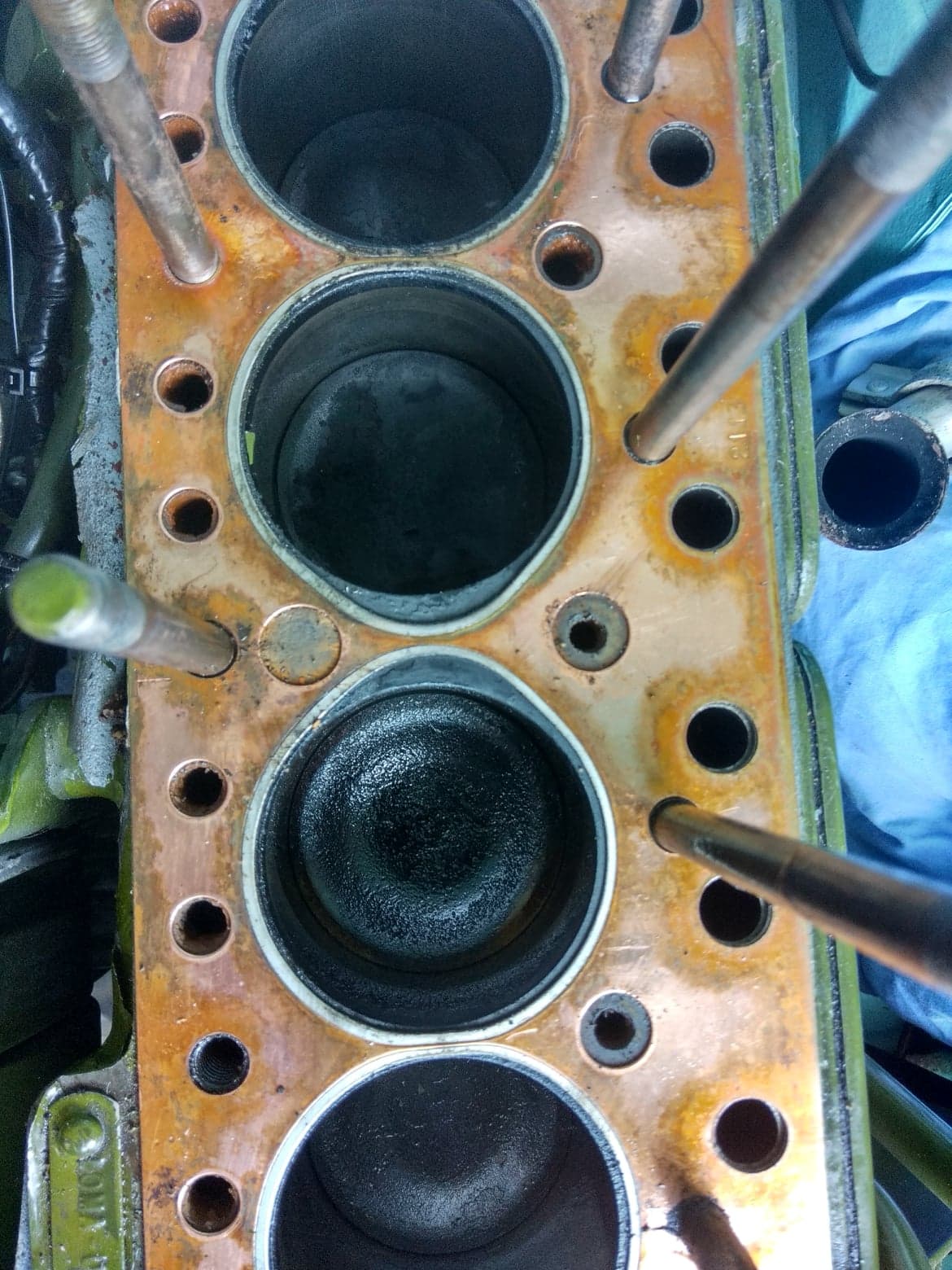

After removing the cyclinder head on my 1098cc engine there are a couple of observations. I would welcome your experienced input.

1. The engine block water channels are badly blocked with an orange coloured substance.

2. The 2 bores at the radiator end of the engine block contain a crusty oil on the surface. The rear 2 bores are drier and not oily. The walls of the piston bore look fine, no marks or scouring.

3. The top of the head itself looks in good condition, no corrosion and free movement of the rocker assembly.

4. The underneath of the head show carbonisation of the valves and seats.

Pictures will be attached to show the condition of the various components mentioned below.

Naturally I want to go with the least cost route.

Would I be fine with the following approach :

a. a clean up of the valves and ports and re-seat the valves ?

b. Do a skim and crack test of the head ? Any recommendations on suppliers ?

c. Cover the valve stem channels and piston chambers then flush out the water channels (How do I clean the water channels ?)

Assuming the engine block just needs a clean up with paraffin, the more expensive route would be to do a head (current head is not unleaded) exchange to a converted one. Any recommendations on suppliers ?

Oh ! Any tips on how to unfreeze the thermostat housing ? Tried WD40 so far.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

- 36114134_10155802792507428_5155845193575956480_n.jpg (221.76 KiB) Viewed 2353 times

- Head Topview.jpg (14.24 KiB) Viewed 2345 times

- Rocker shaft.jpg (68.18 KiB) Viewed 2345 times

- Heater Water valve.jpg (11.76 KiB) Viewed 2345 times

- Valves 1,2.jpg (14.79 KiB) Viewed 2345 times

Thanks forum peers.

Robert

Re: Blocked water Ports

Posted: Sat Jun 23, 2018 8:26 pm

by philthehill

The orange stuff is water jacket crud and is normal. Just flush the engine using an off the shelf flushing agent and use a good quality antifreeze/anti-corrodent when assembled.

The two rear cylinders will run hotter and therefore appear drier if good coolant circulation is not maintained.

Overall the engine components shown do not appear to be too bad from where I am looking from. Clean it all up and put it all back together with a light grind to the valves/valve seats.

If you want to use the valve stem top hat seals (use only on the inlet valve stems) they are best used with the grooved valve guide but you may then need to re-cut the valve seats.

These are the valve guides to use with a 12G202 head. 1275cc (940) head valve guides are too long.

http://www.morrisminorspares.com/engine ... l-p1209547

Use Plus Gas release oil on the studs and soak for some time.

The thermostat housing/studs may need to be heated with a gas torch and as a last resort you may have to cut away the thermostat housing.

Grease the studs on reassembly with copper ease to prevent corrosion.

I would recommend using the later paper thermostat housing gasket and not the original equipment cork type..

http://www.minispares.com/product/Class ... .aspx|Back to

Lightly grease the gasket faces before fitting.

Re: Blocked water Ports

Posted: Sun Jun 24, 2018 7:00 pm

by fasthamster

Thanks for the quick reply and advice.

Sounds like the 2 rear cylinders were not receiving adequate coolant at high engine temperatures.

I have tried a flushing agent but the holes still show orange crud. Is there a manual technique I could use try to clean up the crudded ports ? Obviously no use of power hoses whilst dismantled.

Plus Gas ordered. Fingers crossed it works with mallet persuasion as I don't fancy the alternatives.

What type of grease on the head gasket faces ?

Re: Blocked water Ports

Posted: Sun Jun 24, 2018 7:21 pm

by philthehill

You will not be able to flush the engine fully until the engine is back together and warm.

I was referring to the thermostat housing gasket as regards grease but you can very lightly grease the head gasket as well.

Just ordinary Castrol LM grease or equivalent.

Re: Blocked water Ports

Posted: Sun Jun 24, 2018 8:21 pm

by fasthamster

I did try the flushing prior to the disassemble.

Ok, thanks.

I'll post a wanted ad for a recon head.

Re: Blocked water Ports

Posted: Mon Jun 25, 2018 1:01 pm

by philthehill

I note your comment in your first post regarding the least cost route - therefore personally I would use what I had and not complicate things by looking for a 940 head.

If the engine is used normally and not driven hard the residual Tetraethyl Lead on the valve seats will suffice. Just check the valve clearances a bit more often.

The cost of a fully refurbished 940 head with unleaded valve seats completely outweighs the cost (by several times over) of the small amount of work to get your 12G202 head back to good and serviceable condition.

It is your money and your choice but I know which way I would jump.

If you must have an unleaded reconditioned head get an exchange 12G202 head from ESM.

http://www.morrisminorspares.com/engine ... es-p830272

Phil

Re: Blocked water Ports

Posted: Mon Jun 25, 2018 2:55 pm

by mogbob

Once your Plusgas ( works for me every time ) arrives , build a " little wall " out of Blutac around the exposed studs. This will stop a lot of the Plusgas just dribbling down the outside of the housing .The apertures in the housing/ studs will be surrounded by a " little pool " of Plusgas.

Make sure you have wire brushed the studs well and "dig" out any crud with a sharp pointy object.... before doing the Plus gas.

Hold a lump of wood by the housing and gently bang / tap the wood with a mallet. Move the wood / tapping area around the housing and observe the small bubbles as the liquid sinks into the gap temporarily created. An overnight soak will help .

Over zealous banging , out of eagerness or frustration , will result in a cracked housing.

If this fails as Phil sugggests , application of heat or acknowledge that destruction of the housing will be part of the fall out.

Bob

Re: Blocked water Ports

Posted: Mon Jun 25, 2018 7:19 pm

by fasthamster

mogbob wrote: ↑Mon Jun 25, 2018 2:55 pm

Once your Plusgas ( works for me every time ) arrives , build a " little wall " out of Blutac around the exposed studs. This will stop a lot of the Plusgas just dribbling down the outside of the housing .The apertures in the housing/ studs will be surrounded by a " little pool " of Plusgas.

Make sure you have wire brushed the studs well and "dig" out any crud with a sharp pointy object.... before doing the Plus gas.

Hold a lump of wood by the housing and gently bang / tap the wood with a mallet. Move the wood / tapping area around the housing and observe the small bubbles as the liquid sinks into the gap temporarily created. An overnight soak will help .

Over zealous banging , out of eagerness or frustration , will result in a cracked housing.

If this fails as Phil sugggests , application of heat or acknowledge that destruction of the housing will be part of the fall out.

Bob

Thank you Bob, makes sense and should provide success. I plan to replace the housing, gasket and stat anyway.

Re: Blocked water Ports

Posted: Wed Jun 27, 2018 3:00 pm

by ianmack

If the stat housing won’t come off in one piece and you plan to replace it try cutting carefully down the sides of the stud holes to remove the old housing without damaging the studs.

Re: Blocked water Ports

Posted: Wed Jun 27, 2018 4:04 pm

by fasthamster

ianmack wrote: ↑Wed Jun 27, 2018 3:00 pm

If the stat housing won’t come off in one piece and you plan to replace it try cutting carefully down the sides of the stud holes to remove the old housing without damaging the studs.

Thanks

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]() Thanks forum peers.

Thanks forum peers.