Sure!

https://www.smallfordspares.co.uk/produ ... fold-plate

These were the starting point. Someone on here (Tortron??) mentioned that the bolt pattern for the Ford was the same as the MM. I didn't know for certain that this was the case so rather than spend money on the Ford one I made a pattern in CAD from a standard MM manifold. Ended up being cheaper to get one laser cut locally so was a saving.

I bought a motorbike exhaust from a scrapyard (FZR-something) that supplied the 4 curved downpipe sections. It was fairly new so didn't need much cleaning. I cut the 4 pipes to reach the same level and cut 4 holes in a steel plate to go over the end of the 4 holes. I welded from beneath to get good access and then folded a piece of steel to 'cone' down from the size of the 4 pipes to about 1.5 inches i.d.

The other curves at the bottom of the pipe are just bits of old Marina exhaust and some leftovers from the motorbike.

At the top end I welded the outer faces of the tubes to the big plate and then TIG brazed the insides to get a nice smooth transition. The inlet cost about £20 to be mandrel bent to my specs. Just 2 bends on a metre of steel tube. I had to flatten it to go from round to square for the MM head.

I wanted a single carb for simplicity and then added a little ram pipe for the inlet by forcing an Ali tube over a cone in a bench vice before hammering the ends around a piece of bent rod.

I made one for a friend to fit the pre-war Minor but all the tubes were new custom-bent tubes. Total cost to build was nearly £250.

Next was to copy this silencer/manifold from an Austin. Again, not a complex shape apart from the flange at the bottom. The nose cone was made from 2 pieces of flat sheet bludgeoned into shape using a BFH and a hollowed-out tree stump.

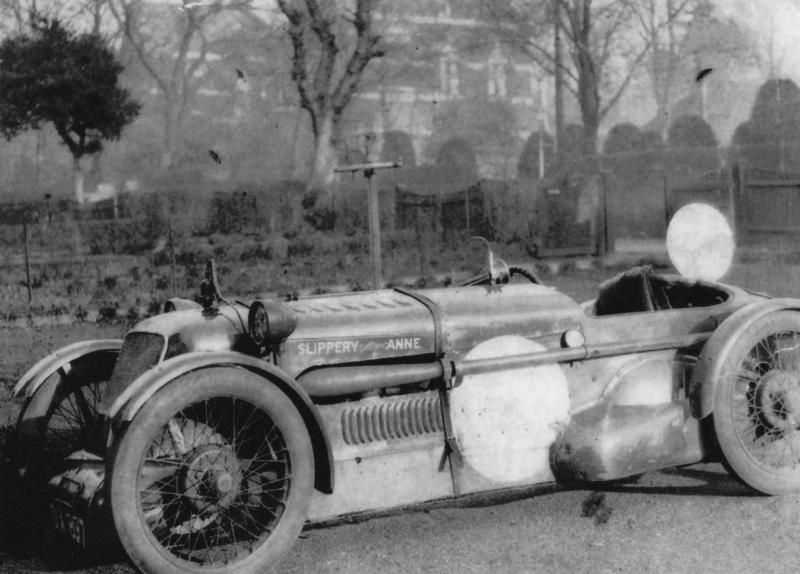

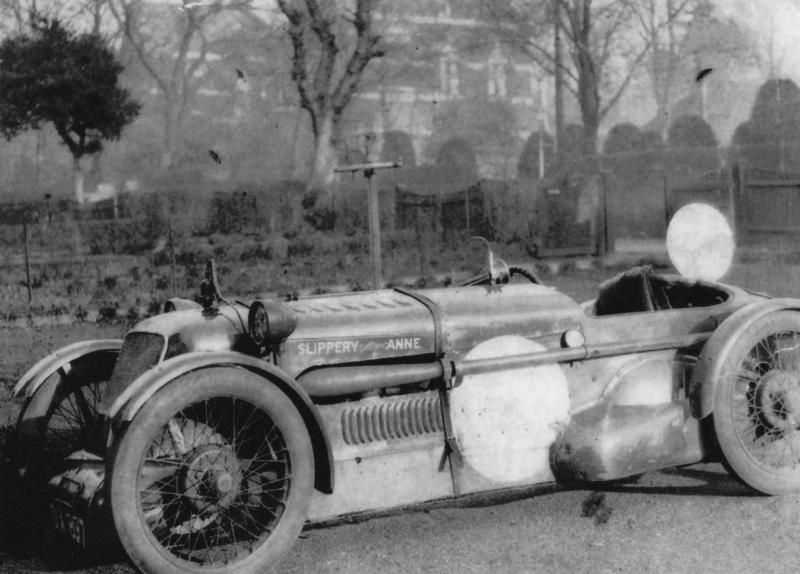

I added these other pics to show what can be done with a little ingenuity and some time.