Page 1 of 2

Removing rivetted crankshaft pulley

Posted: Sun Jan 04, 2009 4:30 pm

by Leo

Any advise on removing the pulley, I have undone the nut but the pulley refuses to budge, I have tried levering it off and also using a 2 leg puller but it will not move. It is the rivetted type and will have to be replaced because with all my failed efforts it is now distorted.

Leo 69 Traveller

Posted: Sun Jan 04, 2009 6:31 pm

by bmcecosse

It usually just more or less falls off. You will need to use two tyre levers against the rim, at 180 degrees - braced against the timing case cover which you should protect with flat sections of timber. In extremis - I suppose you may have to apply some heat - in which case make there is no petrol about - and you will have to renew the timing case oil seal - but it should be replaced anyway if you disturb the pulley.

Posted: Mon Jan 05, 2009 8:47 pm

by rayofleamington

Sometimes they come off easy and sometimes they don't. I've had to resort to using the crowbar on one, but don't lever on the timing case cover unless you want to mash it up!

Posted: Mon Jan 05, 2009 9:05 pm

by bmcecosse

There really is nothing else to lever against - but with protection to spread the load - it should survive!

Posted: Mon Jan 05, 2009 10:59 pm

by bigginger

...but (IME) usually doesn't, and the rim of the pulley buckles too.

a

Posted: Mon Jan 05, 2009 11:11 pm

by Leo

For a while I was thinking it had never happened to anyone else.

This all started out as a fairly simple job to renew a rattling timing chain

It is well and truly stuck, I have ground off the rivets and removed what was left ot the the pressed steel pulley. Now all is left is the casting.

My aim is to get it off without damage to the timing cover.

Heat and a purpose made puller is the next stage, will keep you informed.

Thanks for your advice

Leo

Posted: Tue Jan 06, 2009 12:04 am

by bigginger

Sonds like your best bet - should be easier to get a puller on without the rim there. G'luck

Posted: Tue Jan 06, 2009 11:18 pm

by bmcecosse

Timing cases are cheap and plentiful - just make sure you don't damage the crank! And indeed - good luck!

Posted: Wed Jan 07, 2009 7:37 pm

by pegasus

Hi

I had the same problem removing what was left of my pulley after it decided to seperate while i was out in the car. Anyway some bright spark had for some reason welded the rivets together then used clear mastic (and the bolt) to attatch the pulley to the crank. The only way to remove it was to remove what was left of the pulley as you have done and then use a 3 legged puller and a blowtorch (taking care not to destroy the oil seal in the timing chain cover) to remove the rest of the pulley, a 2 legged puller wont work very well as they tend to twist and dont pull straight. The only other thing i had to do was to remove the front panel as my puller was too long.

Good luck

Mark

Posted: Wed Jan 07, 2009 8:46 pm

by Leo

Mark

I have now tried heat and two legged puller on the flange without success. Not worried about the oil seal as that will be renewed along with the timing chain if I ever get there.

I applied plenty of heat to the flange, the oil was bubbling between the crank and the flange and all kinds of burning smells and yet it still will not budge.

I will take your advice and try a three legged puller and probably have to take the grill assembly off because as you say there is not that much clearance.

Could it be possible that shocking the Starter Dog Nut off has move the Pulley on the crankshaft and somehow caused it to jam?

Leo

Posted: Wed Jan 07, 2009 10:58 pm

by bigginger

You've realised that it's held on by a woodruff key, right? Try drilling through the pulley along the line of the key (and just above it) and you should find it a bit easier to shift. If that doesn't work, try cuting/chiselling the centre in half. Nothing to loose, really

Posted: Wed Jan 07, 2009 11:16 pm

by Leo

Thanks Andrew

I will try drilling into the woodruff slot.

It just seemed that all that knocking to get the nut off could have contributed to the problems in getting the pulley flange off

Will you informed

Leo

Posted: Wed Jan 07, 2009 11:55 pm

by bigginger

Hard to see how it could have, TBH. Mind you, it's pretty damn hard to see how they attach themselves so firmly, but they do

Posted: Thu Jan 08, 2009 12:17 pm

by bmcecosse

Your efforts re starter dog should not have affected it - unless somehow you have managed to twist the end of the crankshaft. The drilling into the hub sounds like the best way forward now.

Posted: Thu Jan 08, 2009 1:10 pm

by 8009STEVE

Small angle grinder. Grind a flat on it and then split with a chisel

Posted: Thu Jan 08, 2009 3:27 pm

by simmitc

As other have said, sometimes they fall off, and at other times it's damn hard work, as you've found. If drilling, take special care to not damage the woodruff key itself. I might be tempted to drill on the opposite side, just a couple of small holes in line to relieve the tightness, and then you still have th option of joining them up with a chisel to split the casting - just try not to drive it even further onto the shaft! Unfortunately you definitely need good access. Best of luck.

Posted: Thu Jan 08, 2009 8:04 pm

by Leo

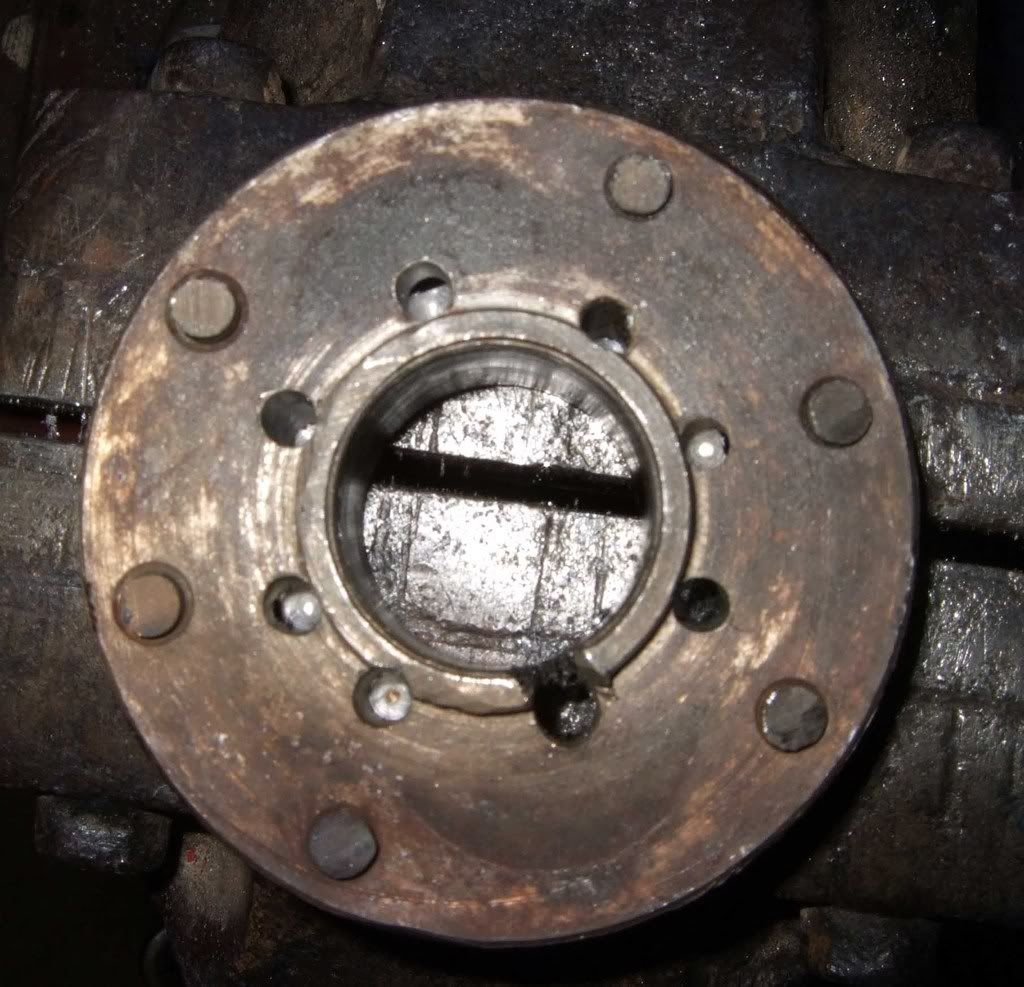

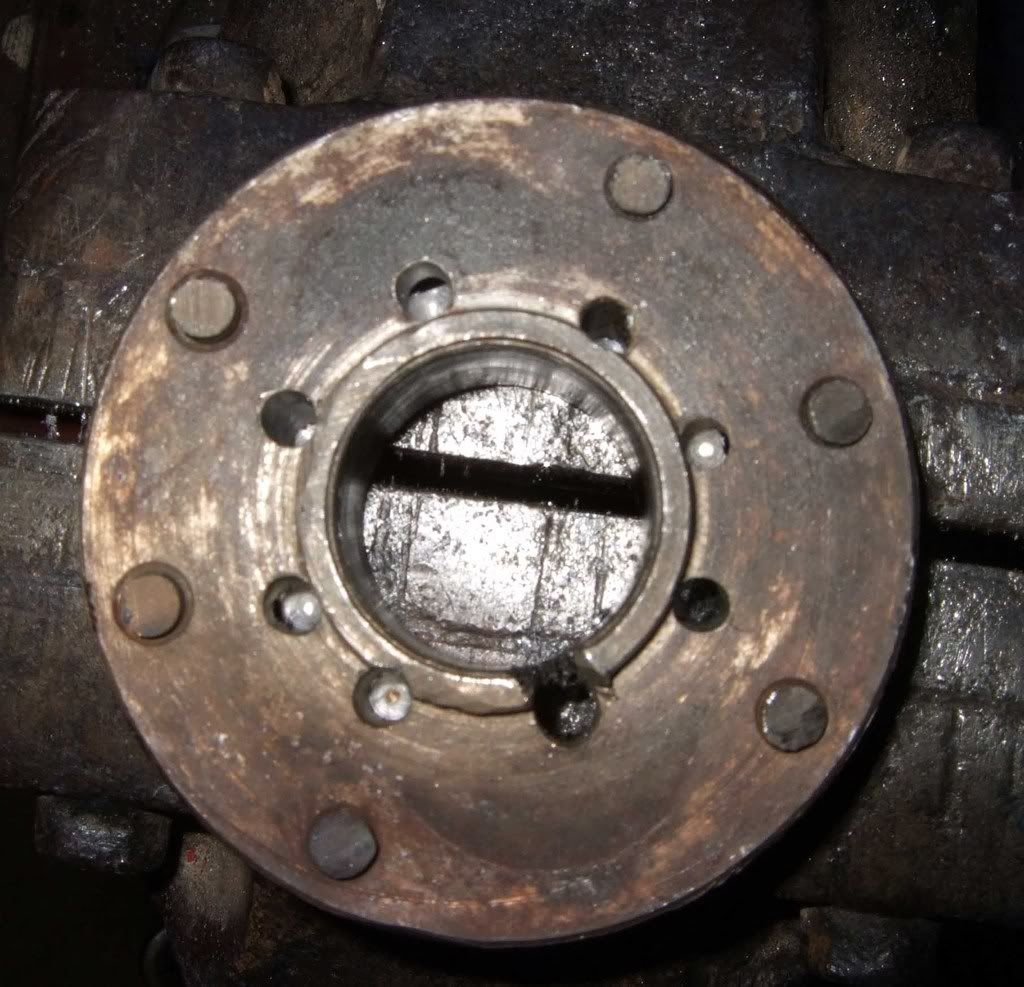

Managed to get another couple of hours in today.

The front of the car is now removed to provide better access.

I have drilled into the flange just above the slot.

The gas torch was playing up, probably because of the cold so I had to abandon heating it today.

The angle grinder method sounds interesting, did think about removing the flange with a grinder, then removing the timing cover leaving the remainder of pulley to be carefully ground and chiselled off.

First of all I will try heating it up once more.

[img]ttp://i160.photobucket.com/albums/t170/lwg_photo/005-2.jpg[/img]

Posted: Thu Jan 08, 2009 11:36 pm

by rayofleamington

Could it be possible that shocking the Starter Dog Nut off has move the Pulley on the crankshaft and somehow caused it to jam?

If the dog was very stuck, it's possible that the crank end has distorted but it's more likely that it's just rusted on a bit.

For removing things like nuts with the angle grinder I have done like one of the recomendations and ground a flat on one side so it can split (often they will split themselves due to being so tight.

However the crank pulley goes through inside the timing cover so you can't get it all with the grinder unless the cover is off

Therefore if you get it to split, you'll only split the outer end. This may be enough to get it free but won't be as good as splitting the whole thing.

I've had to use the angle grinder to remove front disks (2 x Fiestas and 1 x Transit). Cutting a slot in the disk part right down to the inner on opposing sides - then get a chisel into the slot. I've got a bolster chisel about 1mm bigger than the slot which works perfectly. A normal cold chisel could be less effective as the angle will stop it going right into the slot.

Usually this will split with a 'crack' and the 2 bits fall off. If all else fails I'd be tempted to do that.

Posted: Fri Jan 09, 2009 7:58 pm

by Leo

Got it off in the end

Drilled as many holes as I could, then applied plenty of heat while protecting the timing case with sheet metal. It came off using my purpose made puller. Only damage seems to be a hole drilled through the oil thrower washer.

It looks like corrosion may have been the problem, there are some signs of it on the inside of the flange. I think that hole drilled just above the slot done the trick.

Many thanks to all of you for your helpful advice, I must admit there was a time I thought it would never come off.

Only one more question (I hope) do I replace the pulley with a pressed steel one as original or use a later solid one. I prefer to keep things as original if possible but have read that the solid one is best.

Posted: Fri Jan 09, 2009 8:57 pm

by simmitc

Solid one every time - it doesn't fall apart!