Page 1 of 1

birmingham 5 speed converted to hydraulic concentric slave

Posted: Thu Feb 28, 2008 2:38 pm

by superchargedfool

I currently have brum 5 speed using sierra drive plate, moggy pressure plate and release bearing. Its not a good solution and the clamping pressure of the pressure plate is not enough for the power I am running.

Had thought about using uprated pressure plate from jlh (thanks for advice jlh).

But am now thinking why not run ford pressure plate and a concentric release bearing?

Has it been done?

Any ideas?

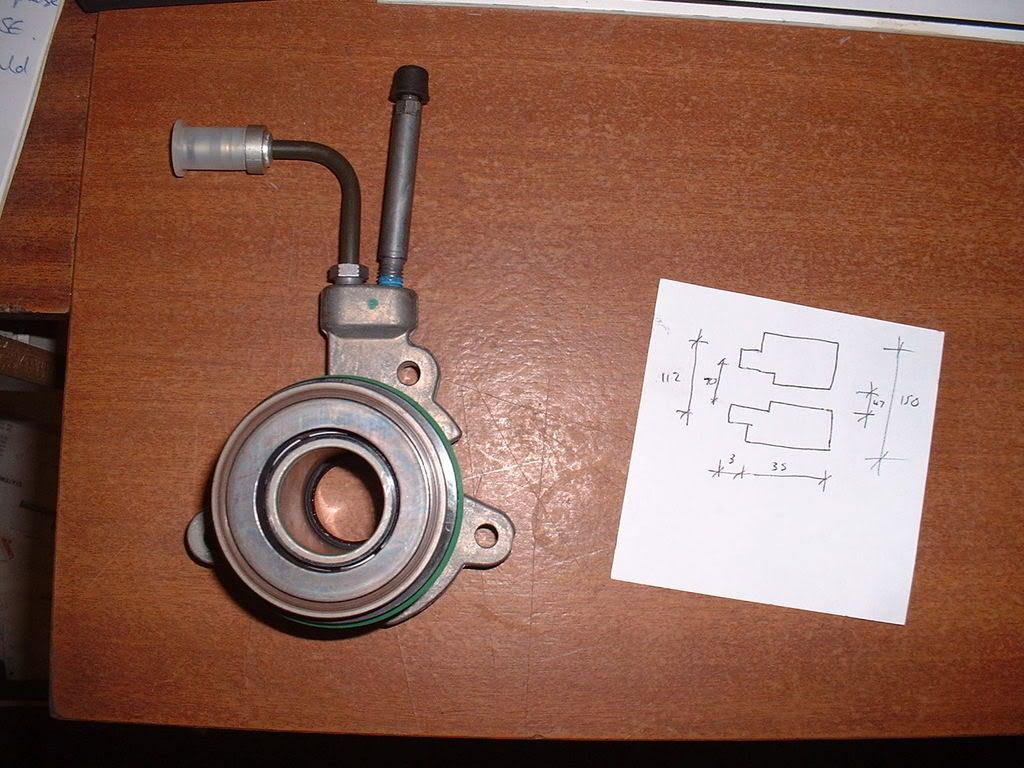

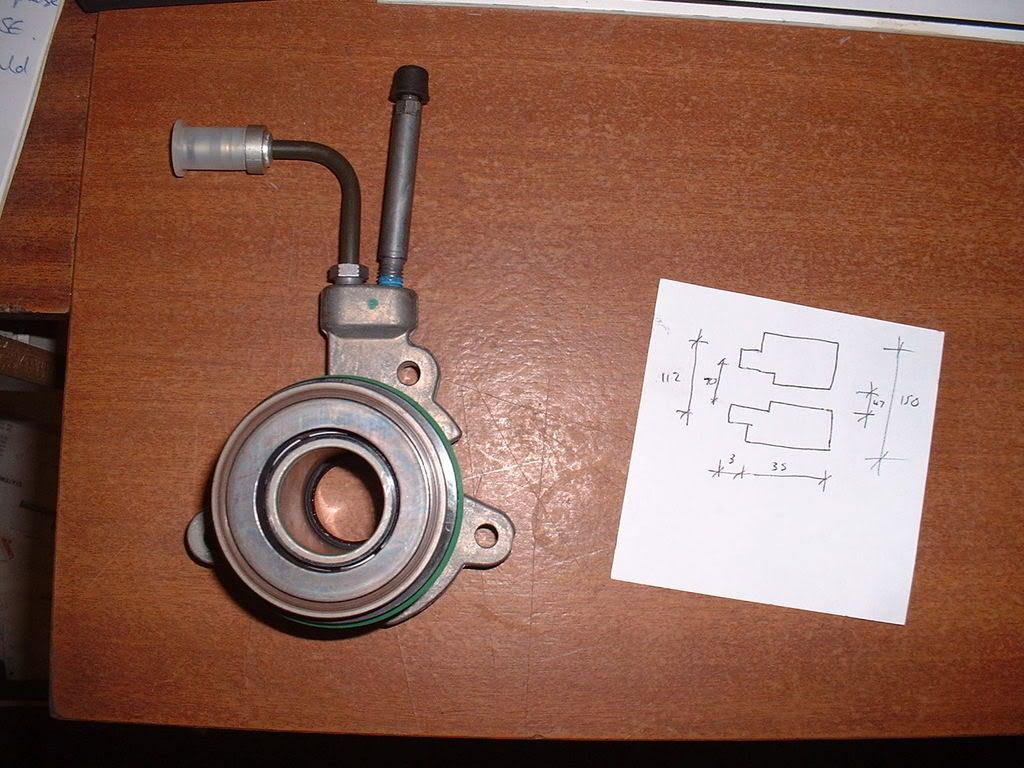

I cant really see a problem myself, was thinking of something like in the piccy cos they are cheap and the feed and bleed are on a nice extended pipe so as to get out of the bell housing.

Posted: Thu Feb 28, 2008 3:21 pm

by jonathon

We have done this on a type 9 to k series so no issues there with the box. the only critical measurement is the depth of the boss/spacer on which you mount the bearing. commercially you would need to allow for both Minor and Ford clutch but in your case its a more simplified criteria.

We have been asked to perform this mod and I have some working drawings I could sent to you, these were supplied by the customer, but I'd rather have the engine,box and other components in front of me before attempting this.

Pop over and we'll give you a hand if you like.

Posted: Fri Mar 14, 2008 2:14 pm

by superchargedfool

well I have decided on a concentric bearing from a 2001 on mondeo because it is reasonably cheap (at trade price), and its small.

Dimensions for the boss to go behind it have been worked out and it is being made as I type. the birmingham bell housing has a 112.5mm hole in the middle of its mounting face so our boss will be 112 mm at its inner end to centralise the boss.

The release bearing has a 46mm inner rear diameter so our boss will be 47mm to centralise it.

This should mean I dont have to centralise or be careful, it will all self centralise.

Boss will bring the release bearing out 36 mm from the back of the bell housing.

The bleed for the concentric as supplied with it will be long enough to exit the bell housing through a half inch hole that I will drill and the supply pipe will enter through where the clutch arm used to be.

All being well, we should be fitted and running again next week.

photos of finished item will follow.

Posted: Fri Mar 14, 2008 5:40 pm

by rayofleamington

Cconcentric slaves need to be mounted as concentric as possible - you've allowed 0.5mm clearance with your boss to the gearbox and 1mm between the boss and CSC.

Ideally the clearances should be smaller as any position error will limit the life of the CSC.

Regading the 3 mounting holes, does your bell housing have mounting holes - I've never been 100% sure if they are overkill as a CSC will normally include a decent preload spring. It would be interesting to know if others have used them without mounting bolts.

Posted: Fri Mar 14, 2008 7:15 pm

by superchargedfool

Regading the 3 mounting holes, does your bell housing have mounting holes - I've never been 100% sure if they are overkill as a CSC will normally include a decent preload spring. It would be interesting to know if others have used them without mounting bolts.

It will have once I have drilled and tapped them. Bell housing is over 10mm thick ally at the back so no problem there.

Posted: Sat Mar 15, 2008 2:55 pm

by Mogwai

This is a mod ive been thinking about if I covert from mecanical to hydraulic actuation . Ford specialist Burton perfomance do a concentric kit for the type 9 which replaces the front cover on the box its not cheap but looks well made has anyone used one before

Posted: Sat Mar 15, 2008 10:27 pm

by superchargedfool

have just looked at the burton part for a type 9 and it looks like they use the same concentric slave as I have come to the conclusion of using. I picked it because its cheap and small, probably same reason they did!

Their mount that replaces the gearbox nose cover is nice and not too expensive but mine is already under way, so will carry on. The burton one would also not be the correct offset unless by a huge stroke of luck so would have either needed shortening or spacing, at least a bespoke one will fit straight in.

Should be done next week, and with more boooooost!

Posted: Sun Mar 16, 2008 1:46 pm

by Mogwai

I'll be intrested to see how you get on. I've fitted a cortina/sierra pressure plate to mine I cant see that there would too much difference in the distance between the clutch & gearbox compared to a ford. im using a modified mechanical linkage it works well enough but would like to go hydraulic

Posted: Tue Apr 22, 2008 1:43 pm

by superchargedfool

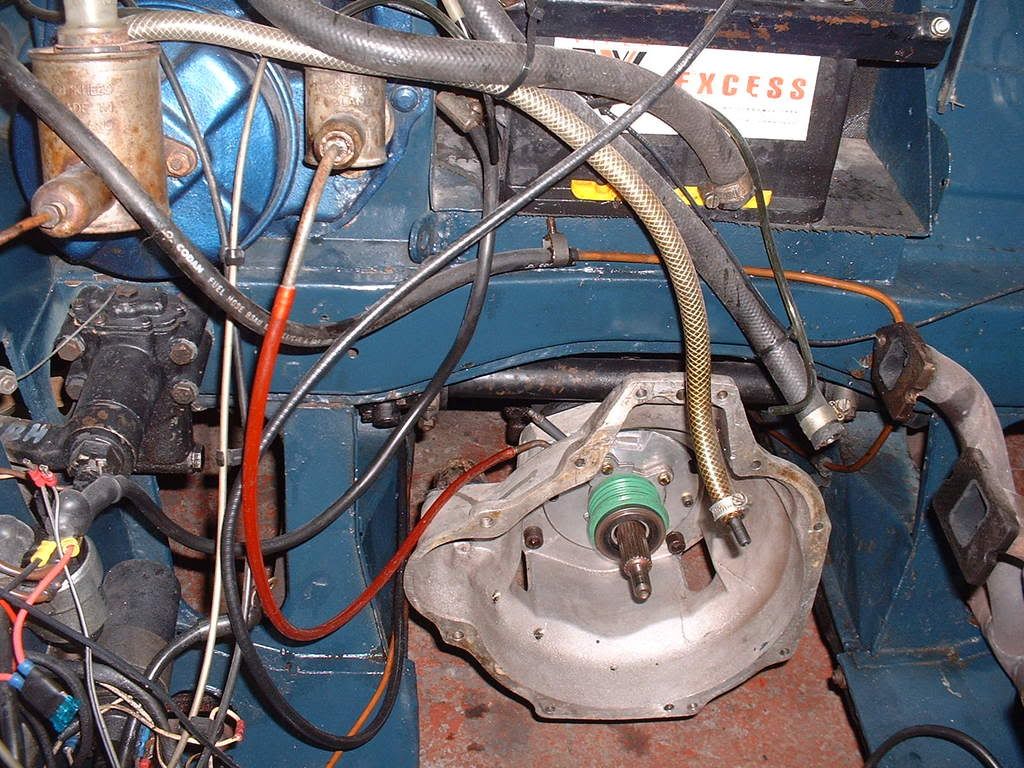

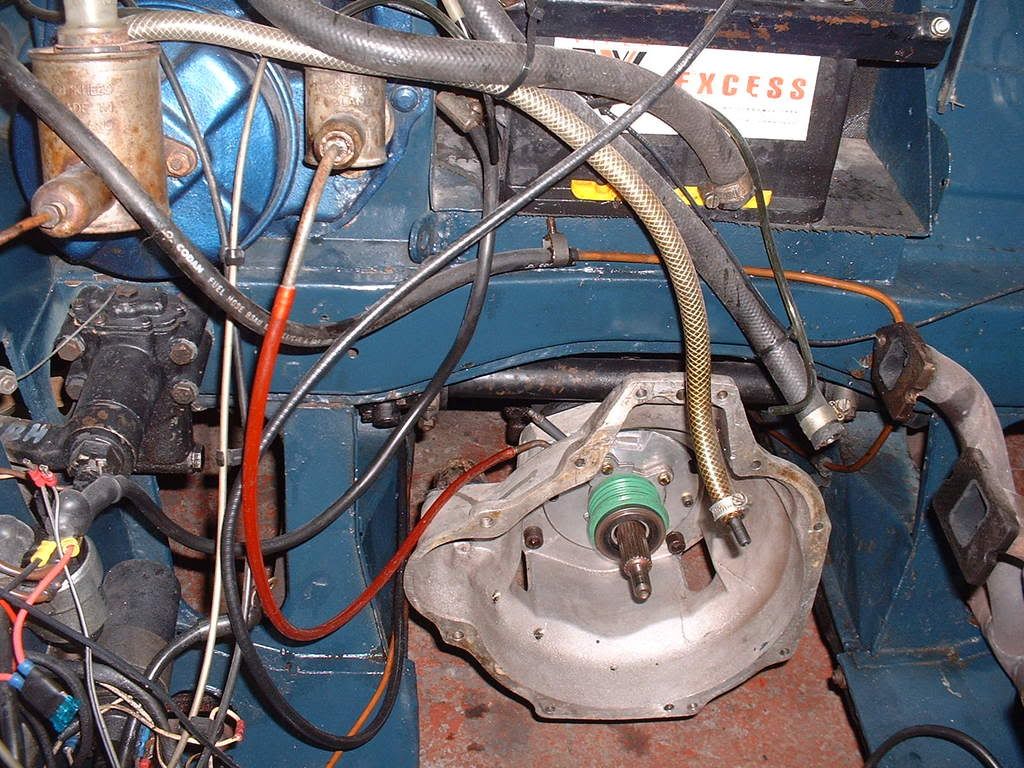

concentric was as easy to fit as I had hoped and is perfect. The concentric came with a short adaptor pipe for its mondeo application which had a union that when removed was used on the end of the marina pipe with only drilling the union out a little bit needed.

So my advice to anybody unhappy with the clutch actuation of a birmingham five speed would deffo be to fit a 2001 on mondeo concentric, it isnt difficult and works superbly.

You can even buy the bit I made from Burton Performance. If the offset of theirs is wrong it can be machined or spacered to suit. The slave has a throw of about 20mm and you only need a few mm so you don't have to be precise about the offset anyway.

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Tue Jan 13, 2015 8:45 am

by Dozer

Hi,

I Hope I have the right person "Superchargedfool"

I see you installed a concentric slave cylinder.

I was chasing some information about setting up the Concentric slave cylinder (CSC). I have a Type 9 Gearbox with a RWD Motorsport bellhousing to a Toyota 4AGE engine.

I see you used a 2001 Mondeo CSC - What model (petrol/diesel, engine size etc)?

Do you know if the Mondeo CSC fits to the Burton mount APC6B?

What release bearing did you use?

I assume the mount replaces the plate which is fixed with 4 bolts around the shaft at the front of the box, with the concentric over the mount and fixed to the mount.

Hope you don't mind all the questions as you don't know me. I live in Toowoomba Australia.

Many thanks in advance

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Tue Jan 13, 2015 11:06 am

by ASL642

Try PM-ing him as he hasn't been on this site since 2012

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Wed Jan 14, 2015 6:34 am

by Dozer

Thanks ASL642

I tried that first, it is sitting in my outbox, being new to the site I thought I have probably stuffed something up. I can't seem to get it out of the outbox.

I have looked at the kits which look good but by the time I convert to the Australian dollar and add postage it is getting a tad expensive. I have a friend who may be able to machine a nose cone if I can get a start from somewhere.

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Wed Jan 14, 2015 6:48 am

by LouiseM

Dozer wrote: I tried that first, it is sitting in my outbox, being new to the site I thought I have probably stuffed something up. I can't seem to get it out of the outbox.

You haven't done anything wrong - messages don't leave the 'outbox' until the recipient has opened it.

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Wed Jan 14, 2015 2:06 pm

by moggiethouable

I cant speak for this particular box but would be interested if anyone had issues with a hydraulic clutch from a Rover V8 box.

I built a kit car once and if the clutch was not depressed around once a month to keep it free it would seize.

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Wed Jan 14, 2015 3:14 pm

by IslipMinor

issues with a hydraulic clutch from a Rover V8 box

Interesting - my elder son and I took a complete Rover V8 and 5-spd box out of an SDI Vanden Plas a couple of weeks ago for a transplant into his MGB. The car has been standing for a while and the clutch was completely seized! Just wondering what we will find when we take the gearbox off the engine?

Re: birmingham 5 speed converted to hydraulic concentric slave

Posted: Wed Jan 14, 2015 9:33 pm

by kevin s

I made an adaptor to use a concentric slave on a type 9 fitted to a lotus twin cam engine ( mechanical actuation fouled exhaust), I kept the original nose piece and machined most of it away so it just supported the front bearing and oil seal, on the front of this I mounted an alloy adaptor to take a scorpio slave (looks the same as the mondeo one above), that was 14 years ago, it still works fine today.

Kevin