Page 4 of 9

Posted: Sat Nov 04, 2006 8:32 pm

by FlyingScot

Flying, I forgot to say, your string is the most inspiring one on the site at the moment. The pace and enthusiasm you show in your approach to the restoration is a pleasure to behold.

Keep it up, and well done to Andy too on the loaning a garage front.

Steve

Posted: Tue Nov 07, 2006 8:50 am

by chickenjohn

expanding foam! LOL- that would trap moisture., nice work again, good to see a freshly zinc primered underside. Although its hard to make out what the last two pics are of, have you cut out the rear floor pan and also the underseat box section and the jack is supporting the spring hanger?

Good work , keep up the impressive pace!

Posted: Tue Nov 07, 2006 8:54 am

by chickenjohn

Looking again, I think I can see you've braced the floor pan with angle iron?

Posted: Tue Nov 07, 2006 8:33 pm

by flying

FlyingScot wrote:Flying, I forgot to say, your string is the most inspiring one on the site at the moment. The pace and enthusiasm you show in your approach to the restoration is a pleasure to behold.

Keep it up, and well done to Andy too on the loaning a garage front.

Steve

what can i say apart from thanks

chickenjohn wrote:expanding foam! LOL- that would trap moisture., nice work again, good to see a freshly zinc primered underside. Although its hard to make out what the last two pics are of, have you cut out the rear floor pan and also the underseat box section and the jack is supporting the spring hanger?

Good work , keep up the impressive pace!

yes you are right but no angle iron,6 axle stands underneath it

forgot to take a picture after the floor went in

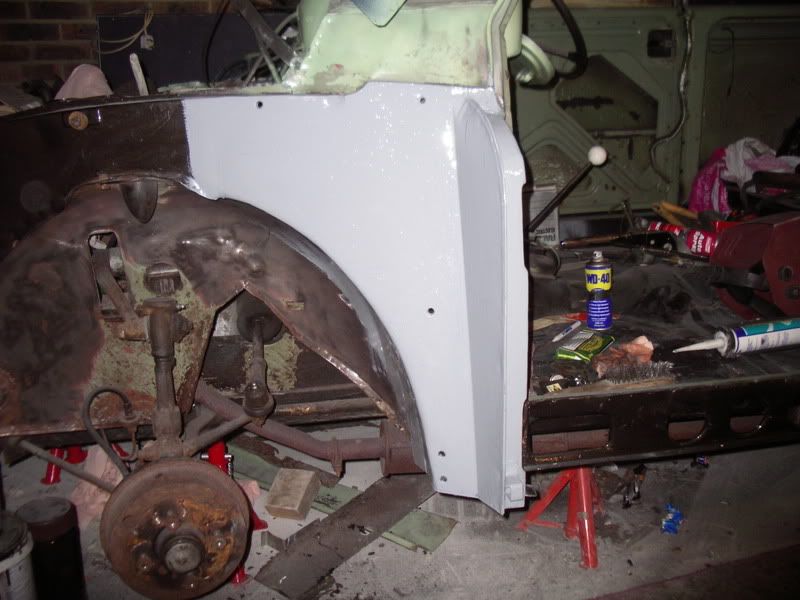

and the panel that goes over this is on has well

Posted: Wed Nov 08, 2006 7:29 pm

by flying

Posted: Fri Nov 10, 2006 8:17 pm

by flying

Posted: Fri Nov 10, 2006 8:52 pm

by JimK

Was there any rust-free metal anywhere in the car before you started? It seems as though you've rebuilt the entire thing...

One question concerning your welding: you said before that you're using gasless - did you learn first using gas shielding or go straight for the fluxcore stuff? I ask because I've read that it's difficult to see what you're doing with the flux giving off clouds of smoke so I wondered how you know what the weld is doing.

Gasless is my only option as I will have to weld outside.

Posted: Fri Nov 10, 2006 9:02 pm

by flying

JimK wrote:Was there any rust-free metal anywhere in the car before you started? It seems as though you've rebuilt the entire thing...

One question concerning your welding: you said before that you're using gasless - did you learn first using gas shielding or go straight for the fluxcore stuff? I ask because I've read that it's difficult to see what you're doing with the flux giving off clouds of smoke so I wondered how you know what the weld is doing.

Gasless is my only option as I will have to weld outside.

it sertainly feels like ive repalced most of the panels ....i think some one must have tried to use it has a boat

my welder can use both gasless and non gasless wire,i went stright to using fluxcord wire but ive also used the gas shieled wire, i use the fluxcord wire which you dont need the gas,im using a solar powered welding helmet which makes welding so much easier

Posted: Fri Nov 10, 2006 9:02 pm

by bigginger

But that doesn't mean that you can't use gas - unless you live somewhere that's very prone to hurricanes...

Soz, posted at the same time as the above

Posted: Fri Nov 10, 2006 9:05 pm

by nebogipfel

JimK wrote:

Gasless is my only option as I will have to weld outside.

Apologies for jumping in here, but welding outside with a MIG is perfectly possible, all you need is to set up a wind break. It helps to nudge the gas pressure up a bit too.

Posted: Fri Nov 10, 2006 10:10 pm

by JimK

nebogipfel wrote:Apologies for jumping in here, but welding outside with a MIG is perfectly possible, all you need is to set up a wind break. It helps to nudge the gas pressure up a bit too.

Ah, I thought it had to be completely still. Where I live is pretty windy, it's hard to block the wind when its blowing.

Hopefully I won't have to do any welding anytime soon but I'll beer that in mind for when I do need to.

This thread needs to be preserved as a "How to rebuild a rotten Minor".

Posted: Fri Nov 10, 2006 10:37 pm

by flying

JimK wrote:

This thread needs to be preserved as a "How to rebuild a rotten Minor".

done

Posted: Fri Nov 10, 2006 11:22 pm

by rayofleamington

Gasless is my only option as I will have to weld outside.

Outside: I did the sills, floor, crossmember, chassis leg, inner wings, A-posts, B-posts, C-posts, boot floor, rear chassis extensions etc.. etc... on the 54 last year using just one gas bottle (a BOC one). I had to turn the gas up higher and therefore used loads compared to welding indoors but otherwise it was no problem.

(no problem apart form the rain the ice and and the snow, but where there's a will there's a way)

I wish I'd got as many pics as flying - this one looks like a fabulous job.

Posted: Sat Nov 11, 2006 7:21 pm

by lofty1000

Great work flying! Well done. When you repaired the door hinge pillars did you tac them on and fit the door to make sure the door fitted ok, I say this because when I repaired mine the door wouldn’t close

, doh! I had to move the pillar forward about 3/8th inch.

Keep Moggying

Lofty

Posted: Sat Nov 11, 2006 8:06 pm

by flying

yes i did tack it before i welded it up....i wernt getting caught by that little thing that could make it hell to get right

aint it fun trying to get it to line up

,i should have that side completed by monday,i got the under floor pans & sill on today ,so just got to make another t peice up for the jacking point arm then finshing it off and start on the rear leaf spring hangers

Posted: Sat Nov 11, 2006 8:56 pm

by lofty1000

Cool, look forward to seeing that, I welded in a new near side rear chassis extension panel a few months ago, bit like peeling an onion

it had about six cover plates.

yeppers the doors are a pig to line up,

I used an old milk crate and blocks of wood to hold it up so that I could the bolts in.

your right about the solar mask too, just got one, ace.

Keep Moggying

Lofty

Posted: Wed Nov 15, 2006 7:38 pm

by flying

Posted: Thu Nov 16, 2006 7:01 am

by chickenjohn

Amazing amount of work done in the time! How do you manage to get so much done so quickly?

Keep it up and keep the posts coming

Posted: Thu Nov 16, 2006 12:53 pm

by nebogipfel

Great work Flying.

I'm not sure I ever had that much energy/enthusiasm, but if I did it was a long time ago

Posted: Thu Nov 16, 2006 8:12 pm

by PAULJ

Hi flying, again nice work. Im thinking of starting my first restoration soon and I just wanted to ask what you think you have spent on bought panels and where you get yours from?

looking forward to starting now!!!!