Page 3 of 4

Posted: Fri Aug 07, 2009 10:19 pm

by Mick_Anik

I've always found there's a kind of magic in the Morris - I can honestly say that my Moggies have almost always given me a hint that something was amiss and needed attention.

A little misfire (sort me out!); suddenly taking longer to start, but still starting (sort me out!) a flickering headlight which went back to normal (sort me out!).

I have rarely broken down, but on the occasions I have, I knew it was coming because I'd had the warning and postponed the work!

I have this theory that the spirit of William Morris lives on in the steel!

Re 'do-it-yourself' - at present-day service charges, imagine how many tools you'll be able to stock up with, and still be in pocket! Get good ones, and look after them. Come to the forum for advice before splashing out, maybe.

Posted: Fri Aug 07, 2009 10:40 pm

by Leo

Has anyone got to the bottom of Rough Running at Tickover?

It seems a very common Moggie problem (me included)

Leo 69 Traveller

Posted: Fri Aug 07, 2009 11:15 pm

by bmcecosse

If the engine is in general poor condition (low and uneven compressions) - it will always be rough. Otherwise - assuming valve gaps are ok - it's just a matter of balancing the carb for mixture and the dizzy for timing!

Posted: Fri Aug 07, 2009 11:38 pm

by Mick_Anik

A tricky one, really......so many variables. I've known a spark plug to misfire at certain revs, but be okay at others.

I'd do this, most of which has been mentioned here, more or less in the following order:

compression test, and if all's well proceed like this, checking for improvement after each step:

dizzy cap inspection/cleanup.....adjust tappets...new plugs....a full dizzy service (including checking the bob-weight springs, and the vacuum advance by taking the pipe from the carb end and sucking, to make sure the dizzy base plate moves)....ignition timing check/adjustment ......new plug leads.....air filter check .....fuel filter check.....carb settings check/adjustment including float chamber level (try temporarily covering the ends of the butterfly spindle where air might be leaking in - paper masking tape holds if you degrease the area)....a careful check of all the electrical connections....

then into less likely sources of trouble: deteriorating ignition coil.....worn/scuffed taper pin ......restriction (muck, a bit of gasket) in the carb jet.

Very unlikely sources of trouble:

dodgy petrol (can happen - try a different supplier if you use the same one all the time).....mice resident in the manifold.....extraterrestrials interfering with your electrical system just for a laugh.....

Posted: Sat Aug 08, 2009 10:17 pm

by Leo

Mick

Very good advice, I have tried at most things you suggest but this evening decided to have a better look at the distributor after removing it from the engine.

I found the baseplate was very reluctant to slide and on closer inspection found that one of the rubber dust covers that go over the baseplate retaining screws had partially broken up and was hindering it's movement.

I have replaced the baseplate with a nearly new one and discarded those rubber dust covers. It now moves nice and easily. Having said that I thought replacing the worn butterfly spindle would improve thing but it did not

Will try and finish it tomorrow and let you know the outcome

Leo 69 Traveller

Posted: Sat Aug 08, 2009 10:42 pm

by Mick_Anik

Hello, Leo!

I'm a bit in the dark regarding he rubber dust covers on the base plate retaining screws.

I've never seen any. My dizzies don't have any. Could you explain further what these are, please?

Could be a terminology misunderstanding.........

Posted: Sat Aug 08, 2009 11:11 pm

by Leo

Mick

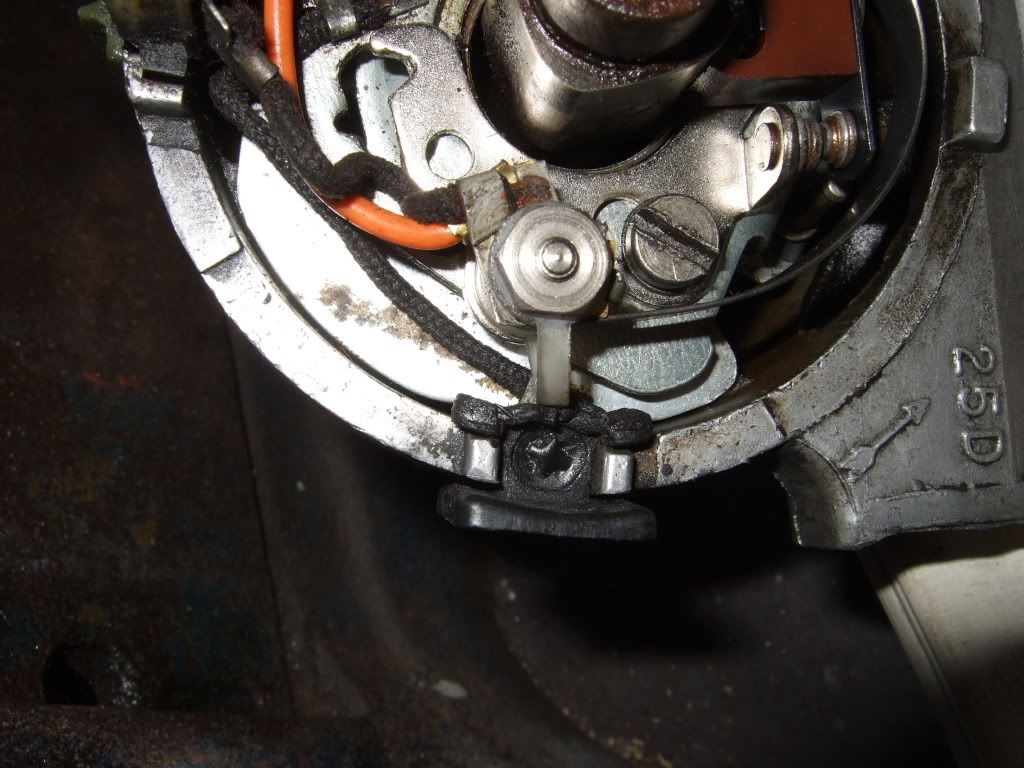

Where the lugs from the distributor cap engage with the body, and where the two screws that secure the base plate to the body there are rubber dust covers.

Not all distributors have these

One of these had broken up and was hindering movement of the baseplate

Could be a red herring as far as rough tickover is concerned

Will post a photo tomorrow evening if this helps

Leo 69 traveller

Posted: Sat Aug 08, 2009 11:45 pm

by Mick_Anik

Happily learning all the time! Good luck!

Posted: Sun Aug 09, 2009 10:26 am

by bmcecosse

New one on me!

Posted: Sun Aug 09, 2009 6:28 pm

by Leo

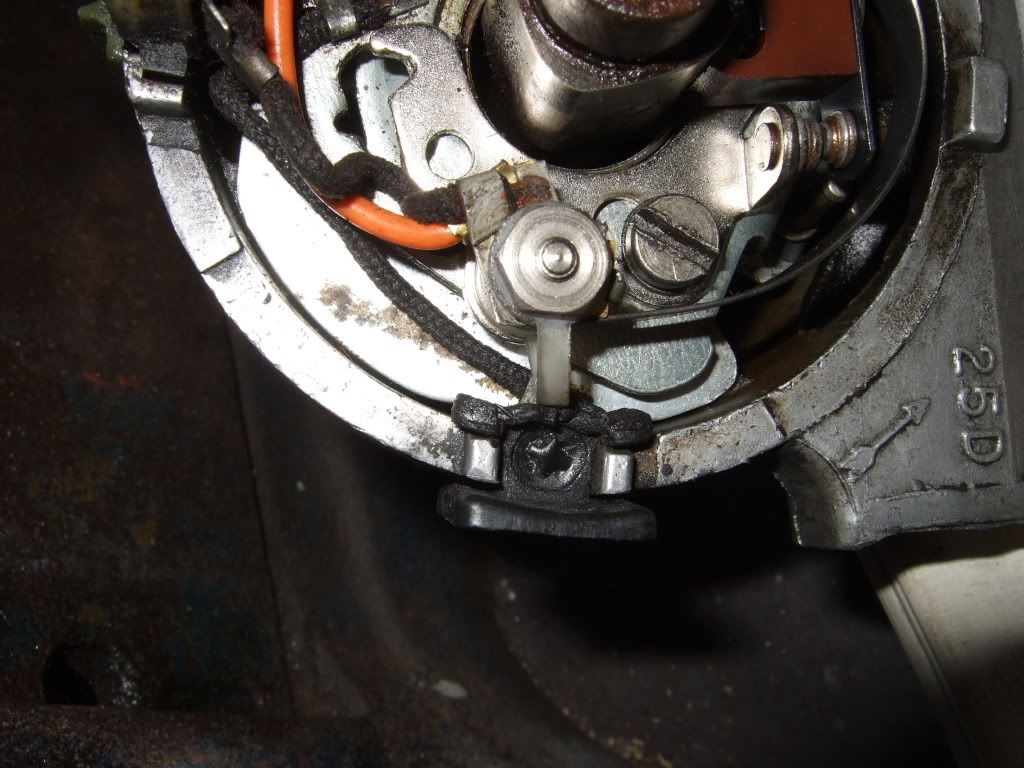

The dust shield is upside down in this photo hence the imprint of the screw head

Posted: Sun Aug 09, 2009 6:34 pm

by Leo

Posted: Sun Aug 09, 2009 6:45 pm

by bmcecosse

Not seen these before - learn something new every day. Were they part of a special 'waterproofing' (or dust proofing) kit I wonder ?

Posted: Sun Aug 09, 2009 7:09 pm

by MarkyB

I was thinking water proofing too.

Maybe an early attempt by Lucas to get a Mini through a puddle?

But then BMC would have seen one before.

Posted: Sun Aug 09, 2009 7:28 pm

by bmcecosse

Maybe they were Mini standard fitting, but I don't remember them - I always used a plastic shield in front of the dizzy.

Posted: Sun Aug 09, 2009 7:44 pm

by Leo

This car has some unusual features and was connected with the development of the Works prototype fibreglass framed traveller.

Maybe this is another idea the original owner was trying out

Posted: Fri Aug 14, 2009 8:04 pm

by Leo

Yesterday the battery failed without warning, would not turn the engine and would not tick over even after starting with the handle. No warning, it had always worked fine up until then. The battery would not accept a charge from the battery charger.

New battery (well overpriced) purchased from Halfords and guess what, the tickover has returned to normal.

All I can assume is that it must have been the battery all the time

Any comments?

Leo

Posted: Fri Aug 14, 2009 8:40 pm

by Mick_Anik

Indulge in a couple of pints of Theakstons Old Peculier, and move on

.

Posted: Fri Aug 14, 2009 9:00 pm

by Leo

Mick

I'll be moving on a bit later with a few pints of Home Brew Real Ale.

Leo

Posted: Fri Aug 14, 2009 9:09 pm

by Mick_Anik

Is there an 'envy' Smiley?

Posted: Sat Aug 15, 2009 8:49 am

by alzax3