Posted: Thu Jul 23, 2009 9:38 am

Morris Minor Owners Club

Promoting the Preservation and Use of the Postwar Morris Minor

https://board.mmoc.org.uk/

Running on 3 cylinders!

Page 2 of 3

Posted: Thu Jul 23, 2009 9:40 am

Shouldn't you be working?jonathon wrote:is that a trailer tent behind yours

Posted: Thu Jul 23, 2009 9:41 am

I'm waiting for tappet spanner [x3] and Plus Gas delivery.

Posted: Thu Jul 23, 2009 10:17 am

Nope , day off today, going to a wedding

running on 3 cylinders

Posted: Mon Jul 27, 2009 12:41 pm

Hi Squiggle

Done my tappets after getting tappet spanners came to conclusion that it was a b****r of a job and may have been easier hanging from the rafters and with an extra arm grafted on let us know if it works and post on a few pics

Ian

Done my tappets after getting tappet spanners came to conclusion that it was a b****r of a job and may have been easier hanging from the rafters and with an extra arm grafted on let us know if it works and post on a few pics

Ian

Re: running on 3 cylinders

Posted: Mon Jul 27, 2009 2:42 pm

OH heck. Don't tell the guy who is offering to do themian.mcdougall wrote:Hi Squiggle

Done my tappets after getting tappet spanners came to conclusion that it was a b****r of a job and may have been easier hanging from the rafters and with an extra arm grafted on let us know if it works and post on a few pics

Ian

Will report back later.

Posted: Tue Jul 28, 2009 12:09 pm

My Dad who was a mechanic for over 40 years reckons it easier to take the engine out to do the valves!! I did mine at the same time as the rebore and still found it an fiddly job even on the bench.

Good Luck

Good Luck

running on 3 cylinders

Posted: Tue Jul 28, 2009 4:54 pm

Hi all

Changed head gasket on my car just over two weeks ago after gasket went had a problem with one of the studs pulling out of the block when tourqueing it down,helicoiled it and got the head back on. Used it for a couple of days and then took it to a local show. When i got home lifted the bonnet to find 4 of the nuts had oil seeping out and one had water seeping out, have to admit two were seeping oil before gasket went but more now, i asume it is because studs go into oil ways and water jackets.I am going to take head back off remove offending studs, replace using thread seal and hope none need helicoiling, does anyone have similar experience and did they do the job another way

Regards Ian

Changed head gasket on my car just over two weeks ago after gasket went had a problem with one of the studs pulling out of the block when tourqueing it down,helicoiled it and got the head back on. Used it for a couple of days and then took it to a local show. When i got home lifted the bonnet to find 4 of the nuts had oil seeping out and one had water seeping out, have to admit two were seeping oil before gasket went but more now, i asume it is because studs go into oil ways and water jackets.I am going to take head back off remove offending studs, replace using thread seal and hope none need helicoiling, does anyone have similar experience and did they do the job another way

Regards Ian

Posted: Tue Jul 28, 2009 5:20 pm

I replaced all the studs in mine with new as the old ones were very badly rusted away at the bottom. I dont think they go into the oil ways just the water ways on the manifold side of the engine. I didnt use any sealer just made sure the studs were really tight before replacing the head.

running on 3 cylinders

Posted: Tue Jul 28, 2009 6:49 pm

Hi David

If they dont go into oilways where is the oil coming from as i dont think any oil goes into the head. Where did you get new studs from.

Regards Ian

If they dont go into oilways where is the oil coming from as i dont think any oil goes into the head. Where did you get new studs from.

Regards Ian

Posted: Tue Jul 28, 2009 8:22 pm

The mystery of the oily studs. I have some of those. They must go into the oilways I can't think of any other way the oil could could get to them. There are certainly no oilways in the head.

On the subject of adjusting tappets, it is possible to do it with two spanners.

Hold the cam follower (the bottom one) with one spanner, slacken the lock nut (the centre one) just enough to be able to move the adjuster (the top one). Take the spanner off the lock nut and use it to move the adjuster, with the feeler gauge between the adjuster and the valve. There should be just enough tension to be able to set the adjuster without moving the lock nut. When set, tweak the locknut tight.

Adjust the valves as the opposite valve opens and mark them with a piece of chalk. No need to do them in order.

On the subject of adjusting tappets, it is possible to do it with two spanners.

Hold the cam follower (the bottom one) with one spanner, slacken the lock nut (the centre one) just enough to be able to move the adjuster (the top one). Take the spanner off the lock nut and use it to move the adjuster, with the feeler gauge between the adjuster and the valve. There should be just enough tension to be able to set the adjuster without moving the lock nut. When set, tweak the locknut tight.

Adjust the valves as the opposite valve opens and mark them with a piece of chalk. No need to do them in order.

Posted: Wed Jul 29, 2009 9:49 am

I've got a late MM block here that I bought years ago. None of the head bolts appear to go through into anything but metal. No waterways or oilways pierced Might it be gunk from the threads being boiled and squirting back up the stud?

I had thought about re-bolting the engine when I came to rebuilding it (after doing one aero engine and my 1275, so, maybe next year??) and wondered about getting metric AN/MS or NAS aero-grade bolts and lathing the shafts down to the thickness of the innermost diameter of the thread over about 80% of the grip length (end of thread to bottom of bolt head) to allow some gap between the bolt and the sides of the hole in the iron or alloy head. There is also the advantage that the stretch of the bolt is now more equal along the length.

There is a nice "How to" book on nuts, bolts and washers etc by a chap called Carroll Smith. Worth a read if you can find it. 1001 things you didn't know about bolts!<br> <br>

<br>

I had thought about re-bolting the engine when I came to rebuilding it (after doing one aero engine and my 1275, so, maybe next year??) and wondered about getting metric AN/MS or NAS aero-grade bolts and lathing the shafts down to the thickness of the innermost diameter of the thread over about 80% of the grip length (end of thread to bottom of bolt head) to allow some gap between the bolt and the sides of the hole in the iron or alloy head. There is also the advantage that the stretch of the bolt is now more equal along the length.

There is a nice "How to" book on nuts, bolts and washers etc by a chap called Carroll Smith. Worth a read if you can find it. 1001 things you didn't know about bolts!<br>

Posted: Wed Jul 29, 2009 12:33 pm

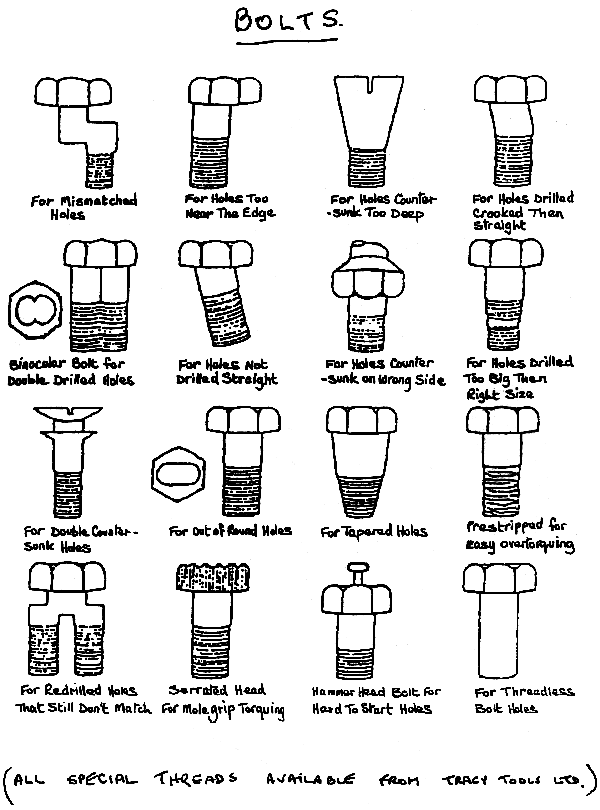

RobThomas wrote:1001 things you didn't know about bolts!

running on 3 cylinders

Posted: Wed Jul 29, 2009 3:08 pm

Ha Ha Ha

Posted: Wed Jul 29, 2009 3:51 pm

Nice one Alex!!!!!!

Ian, I just bought metric threaded bolts and cut them to the right length, tapped out all the holes and tightened them into place. Mines has the early engine without the water pump and the studs on the manifold side definately go into the water way.

Ian, I just bought metric threaded bolts and cut them to the right length, tapped out all the holes and tightened them into place. Mines has the early engine without the water pump and the studs on the manifold side definately go into the water way.

Posted: Wed Jul 29, 2009 4:02 pm

laex_holden,

Well done - not seen that before!

Well done - not seen that before!

Posted: Wed Jul 29, 2009 4:08 pm

Hmmm, yes my proof reading and typing skills are sooooper

Posted: Wed Jul 29, 2009 6:52 pm

Actually I just preffered the spelling you'd used so I copied it ;-)Hmmm, yes my proof reading and typing skills are sooooper

I meant I'd not seen the drawing before. ;-)

Posted: Wed Jul 29, 2009 7:52 pm

Mine always seems to come out as Axle if I'm typing too fast, must be Freudian......

Posted: Wed Jul 29, 2009 9:23 pm

Back on the subject of oily studs, it is the centre row studs between cylinders 1 & 2 and 3 & 4 so I guess I am burning a bit of oil and the excess is getting past the head gasket to the studs. There is also a trace of oil on the 3rd stud back over the water jacket. The engine has to come out for a rebuild so the problem will be solved.