Page 7 of 13

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Fri Jun 14, 2019 12:15 pm

by ndevans

Thanks Phil, I'll see if I can source a socket locally.

I got the nut off with a spanner, which is how I did it up after the last rebuild. It's lasted 2 yrs like that, and with the washer tab bent up, it's not going anywhere.

If you're at the National, I owe you a beer!

Cheers N

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sat Jun 15, 2019 10:56 pm

by ndevans

Got the sump, timing cover, backplate and head on now. Got the flywheel on as well, but having a job tightening up the bolts to 40lbft without the crankshaft turning.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 12:16 am

by Bowie69

Screwdriver in the flywheel teeth, or put a socket on the front crank pulley bolt.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 6:41 am

by oliver90owner

Should have thought about order of operations! A block of wood between the crank and crankcase would have easily prevented the crank turning, while tightening the bolts! Flywheel fitted before sump is the sensible way to reduce effort.

I’ve also seen so many who don’t think of the moments incurred when tightening their wheel nuts. Same applies, in this instance, to the flywheel bolts. Always tighten across the centre - that way the moment is a spanner length (times force, of course), less the distance between point of application and fulcrum, not in addition to the distance between fulcrum and bolt. Application of simple basic Physics principles.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 8:26 am

by ndevans

oliver90owner wrote: ↑Sun Jun 16, 2019 6:41 am

Should have thought about order of operations! A block of wood between the crank and crankcase would have easily prevented the crank turning, while tightening the bolts! Flywheel fitted before sump is the sensible way to reduce effort.

I’ve also seen so many who don’t think of the moments incurred when tightening their wheel nuts. Same applies, in this instance, to the flywheel bolts. Always tighten across the centre - that way the moment is a spanner length (times force, of course), less the distance between point of application and fulcrum, not

in addition to the distance between fulcrum and bolt. Application of simple basic Physics principles.

Good point, didn't think of that.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 8:35 am

by philthehill

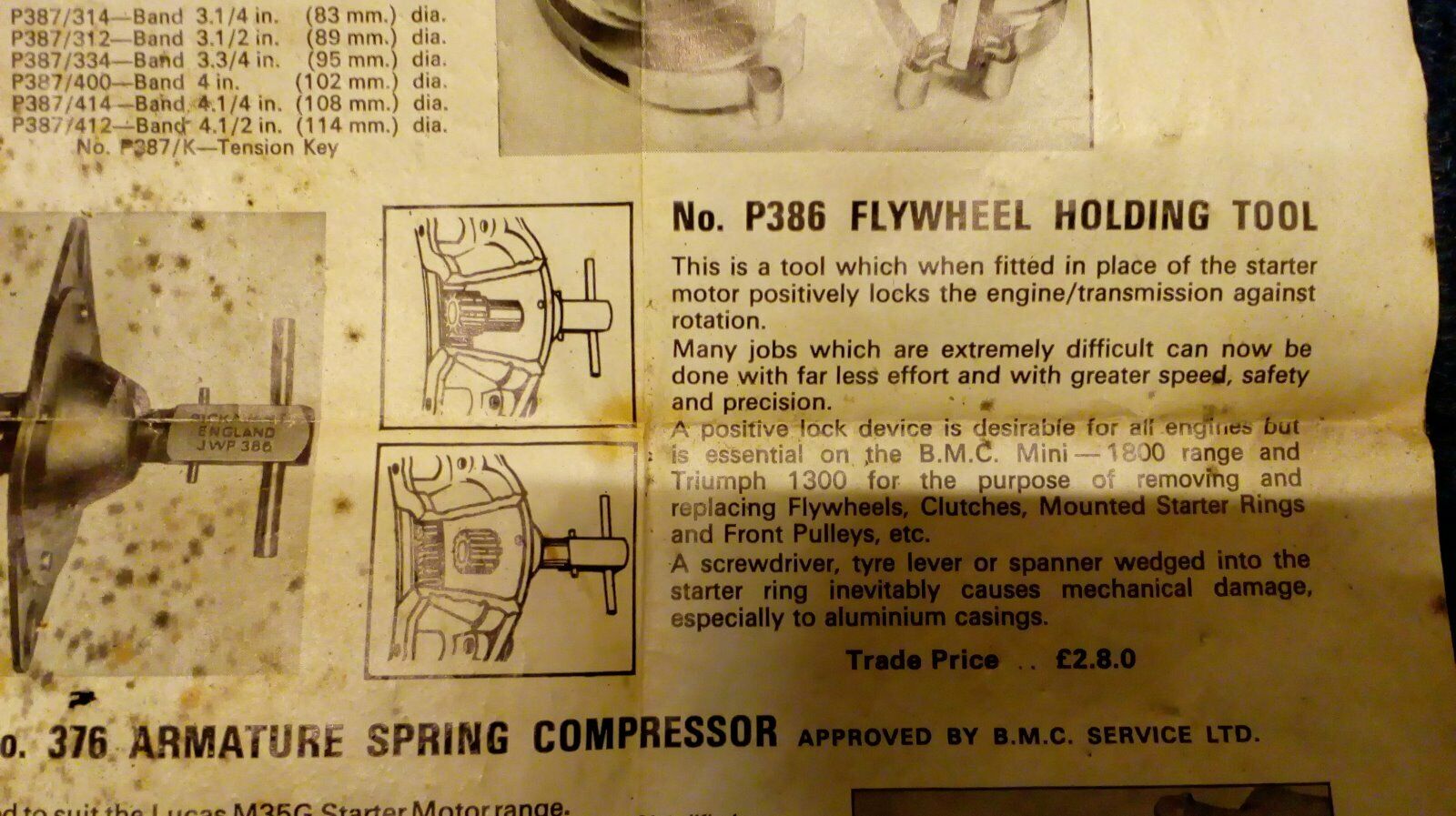

If you want to do the job without damaging yourself , the tools being used and/or the engine you do need a flywheel locking tool.

I have a similar tool to that in the link below which is a modified (so that it can be swung out of the way to rotate the engine) Sykes Pickavant Pt No: 085105 and a Sykes Pickavant Pt No: P386 flywheel locking tool.

https://www.ebay.co.uk/itm/flywheel-loc ... Sw9KhaKqf8

- Flywheel locking tool.jpg (223.06 KiB) Viewed 2368 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 10:49 am

by ndevans

I improvised.....

- IMG_20190616_104820~2.jpg (1.01 MiB) Viewed 2354 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 10:58 am

by philthehill

Well done.

A man after my own heart.

As an aside - your photo above clearly shows the adapter required to fit the ESM modified flywheel to the 1275cc engine.

Do you have a photo off the flywheel off the crankshaft which shows the adapter fitted into the rear end of the crankshaft or into the flywheel?

I cannot make out from your June 8th photo above as to whether the adapter is fitted or not.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 11:47 am

by ndevans

There isn't an adapter, it's a Minor flywheel drilled for the 6 bolt Marina crank, exchange from ESM. Should there be an adapter?

On the subject of flywheels, the Minor manual says the 1/4 mark on the flywheel should be aligned with the crankshaft throws of no 1 & 4 cyl. I can't do this, because the locating lugs only allow the flywheel to be fitted in line with 2/3. Can't say I've noticed it being rough, but is this a problem?

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 3:40 pm

by philthehill

The end of the Marina crankshaft (pictured below) is flat except for the one location dowel and a slight central recess..

- 100_2175.JPG (1.56 MiB) Viewed 2329 times

You appear to have the adapter fitted as the rear face of the flywheel is near level with the rear face of the adapter. If the adapter was not there there would be a distinct step between flywheel and the rear of the crankshaft.

The Marina first motion shaft bearing as can be seen above is a needle roller and the Minor a Plain oilite bush.

The Minor oilite bush is 1/2" inside diameter and the outside diameter is 5/8" and is 5/8" in length.

I do not have the dimensions of the Marina needle roller first motion shaft to hand but they are on here and can be found by using the search facility and see also comments by midget.

The rear face of the oilite bush must be 5/8" from the rear face of the block.

The flywheel can be placed on the crankshaft as required - it will not throw the engine out of balance.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 3:48 pm

by ndevans

Is this the adapter? The centre boss?

- IMG_20190616_153613~2.jpg (762.76 KiB) Viewed 2335 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 4:05 pm

by philthehill

That appears to be the adapter.

Try the Minor oilite bush in the adapter and see if it fits. Come back on here either way please.

The adapter should be Loctited into the crankshaft recess.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 4:24 pm

by ndevans

Oolite bush? Not sure what that is!

The crankshaft flange is the original Marina item, unmodified. There's nothing else on or in it. Can't take it apart now, but I'll see if I have any other photos.

The flywheel is an exchange modified one from ESM, drilled for 6 bolts. The original Marina flywheel is here:-

- IMG_20190616_162348~2.jpg (755.03 KiB) Viewed 2329 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 4:35 pm

by philthehill

The oilite bush (Pt No: 1A1559 MOSS)) is the bush that fits into the rear of the crankshaft and supports the front end of the first motion shaft.

The oilite bush is a bush made from porus material that absorbs and retains oil.

https://en.wikipedia.org/wiki/Oilite

The oil retention ability is required as there is no way you can lubricate the bush once the gearbox is fitted.

The Marina needle bearing first motion shaft on the other hand is filled with grease and sealed with a lip seal once the first motion shaft is fitted.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 4:48 pm

by ndevans

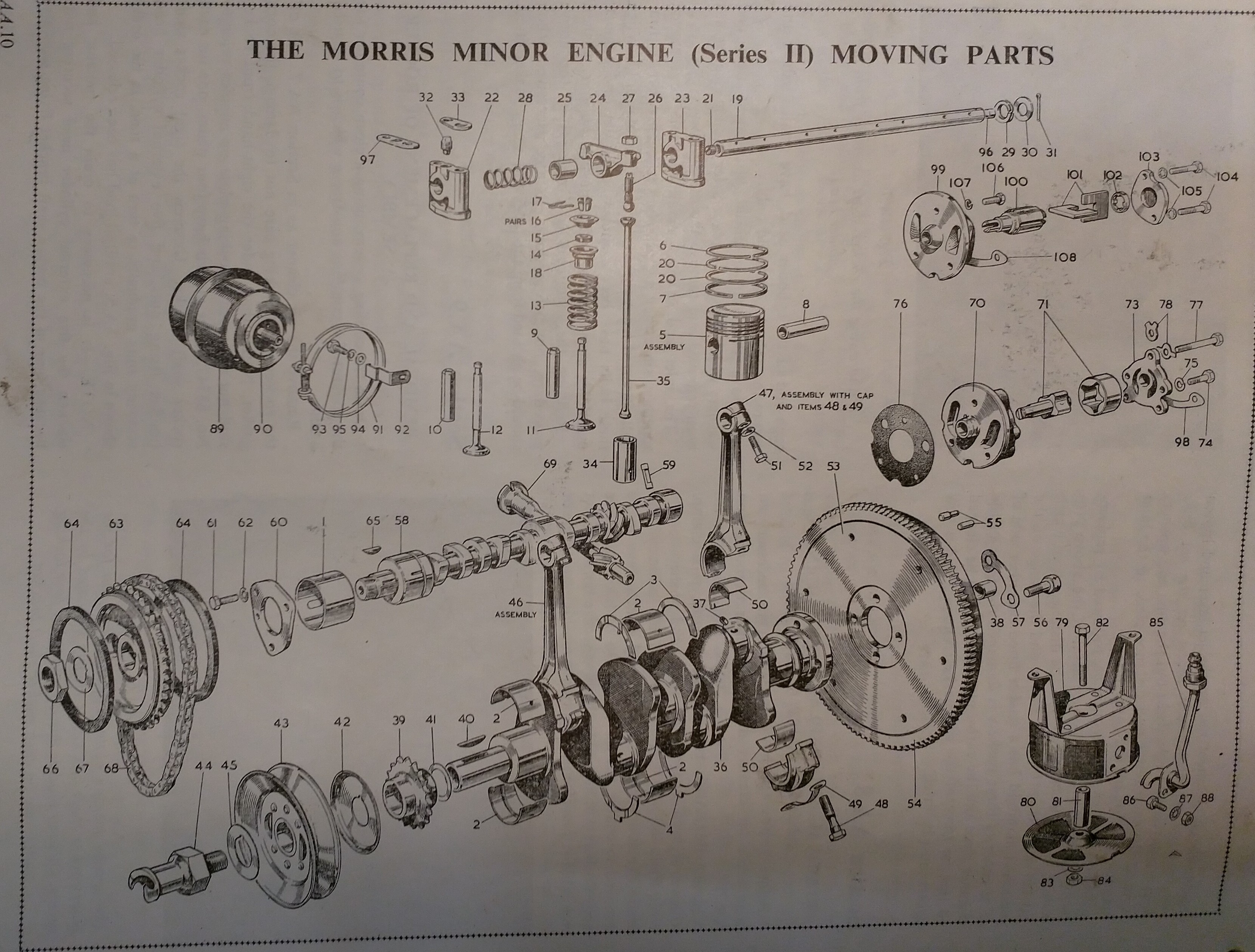

Ah, is it part no. 38 in the diagram below, listed as Bush-drive gear?

If so, it has not been present on this engine, or the 1098 that preceded it, since at least 1998, if not longer.

Is it the oolite or needle roller bush I need?

Cheers N

- IMG_20190616_164541~2.jpg (1.61 MiB) Viewed 2320 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 6:35 pm

by philthehill

No: 38 it is.

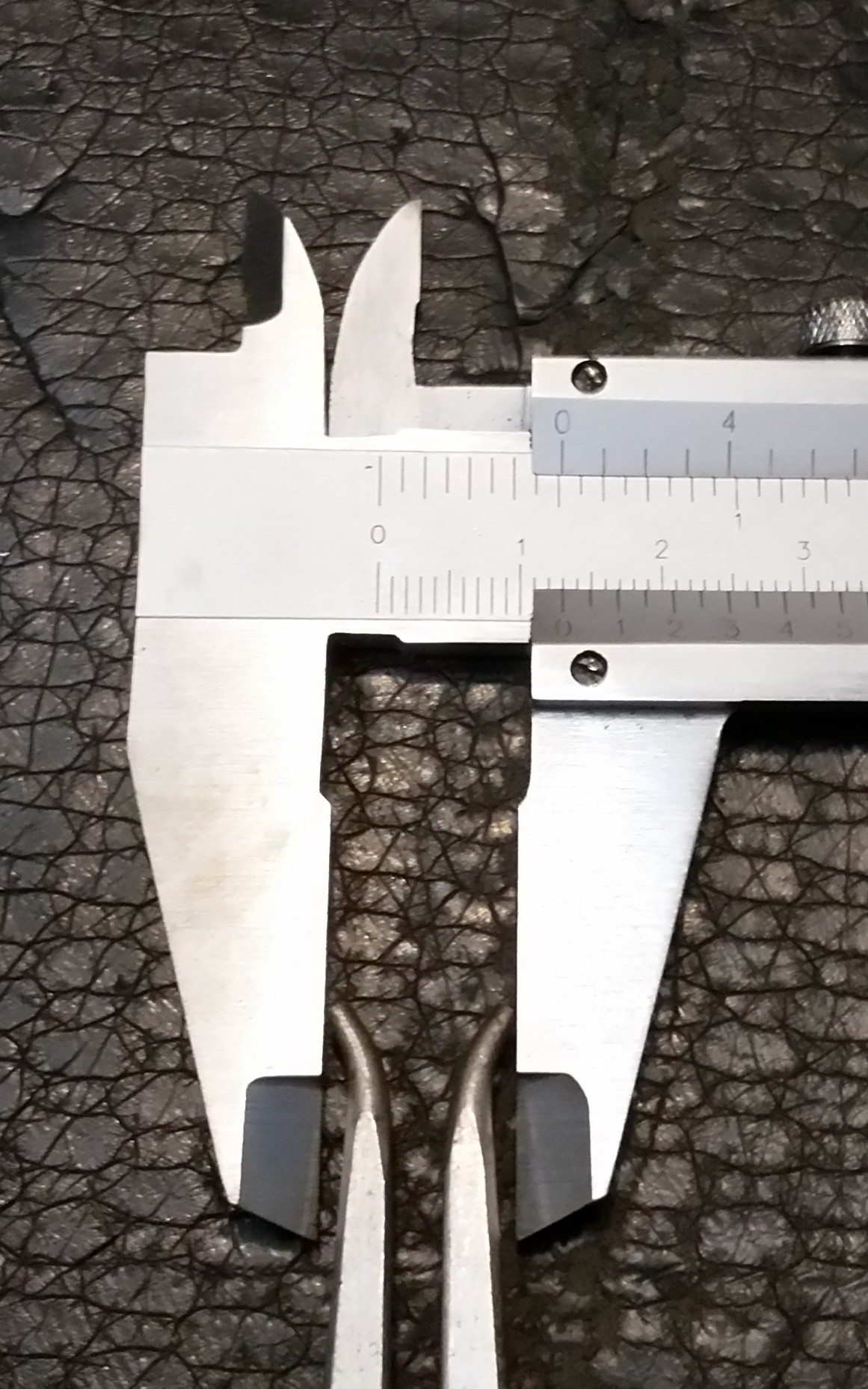

Measure the inside bore of the adapter - for the oilite bush the bore should be 5/8".

Then please come back on here with the measurement.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 7:42 pm

by ndevans

Measured as best as I could, the i/d of the crankshaft flange would seem to be a shade over 1/2". You can just see the inner behind the flywheel in the lower photo.

The inside bore of the actual adapter is a shade under 3/4".

Haven't measured the 1st motion shaft on the gearbox yet, but it looks like 1/2".

- IMG_20190616_193812~2.jpg (375.89 KiB) Viewed 2310 times

- IMG_20190616_193840~2.jpg (646.76 KiB) Viewed 2310 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 8:15 pm

by philthehill

The first motion shaft bearing surface is 1/2" dia.

It looks as if there is a first motion shaft bearing at the back of the adapter.

Measure the inside diameter at the rear and if you can measure the distance the rear face of the first motion shaft bearing (if fitted) is from the rear face of the block. You may have to do a bit of adding and subtracting to get to the final measurement.

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Sun Jun 16, 2019 10:30 pm

by ndevans

I think what you're seeing at the back is inside the crankshaft flange. Using a bent paperclip, I've measured the distance from the face of the flywheel to the inside edge of the bush in the flange as ~50mm. That's pretty much twice the thickness of the flywheel.

I think the adapter in the flywheel has no bush, but there is a bush inside the crankshaft flange. The total depth inside the crankshaft flange is about 61mm.

- IMG_20190616_220340~2.jpg (1.14 MiB) Viewed 2298 times

Re: Engine in bits for a rebore-anything else worth doing?

Posted: Mon Jun 17, 2019 7:46 am

by philthehill

You are right in that there is a bush in the rear of the crankshaft.

That bush is much thicker than the Minor bush.

All I can suggest now is that you carry on with the engine re-build whilst keeping an eye on the position of the first motion shaft relative to the bearing in the back of the crankshaft.