Richard

Blame it on Brexit

The cranks have been cross drilled with restrictors, wedged and balanced in both static and dynamic modes.

After the work was carried out the cranks were tuftrided and checked for trueness.

The flywheel, clutch cover and crankshaft pulley/damper (2 part lightweight racing Cooper S) were part of the crankshaft static and dynamic balance.

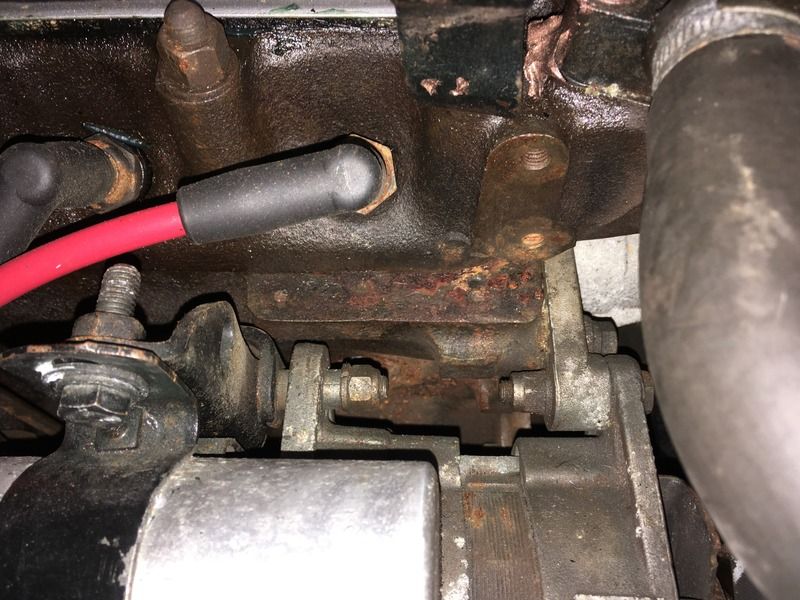

A 4 bolt centre main cap helps to hold it all together.

The above work was done by Oselli.

The Cooper 'S' rods have been polished and balanced as well which helps too. That work was done by Manx Racing.

Note:- There are two specifications of materials used in the production of the Cooper S rods EN24V was the original spec and later EN21 was used for both Cooper S and the 1275cc Midget/Sprite engine.

Mark

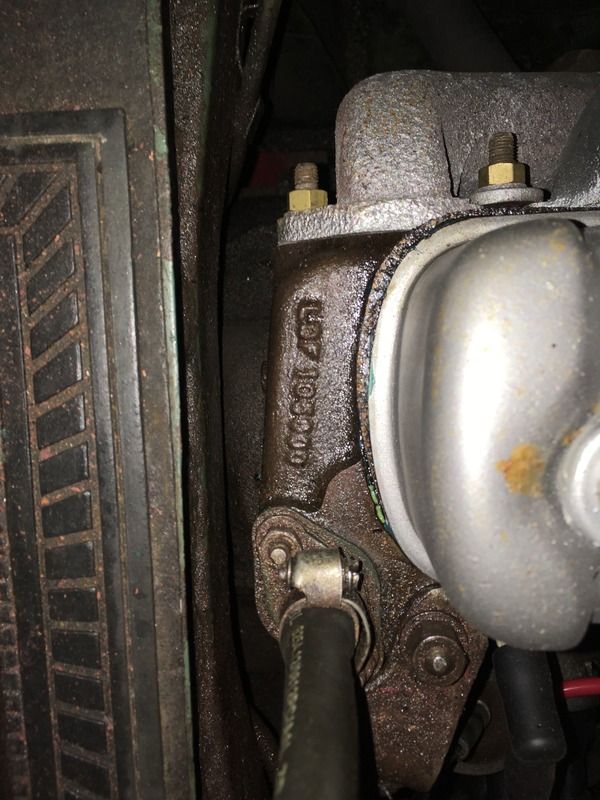

The numbers may well be the engine number; and to keep all the parts together the numbers were stamped on the various items.

Stamping the numbers on engine parts is quite common especially when there is the possibility that parts could become separated when the engine is overhauled.

What size bores/pistons do you have?

It is highly likely that your engine number tag got separated from the engine if and when the block was re-bored.

If the engine has been re-bored it is not ex factory condition unless silver or gold seal reconditioned and then the engine would have a reconditioned engine number attached in place of the original.

Phil