A thousand miles or so of trouble-free daily commuting passed...

Friday night I resealed the downpipe because it come loose and was making a noise. After I fixed that, the engine still sounded noisier that in should - sort of "clattery."

Saturday morning I drove 250 miles to Glasgow. When I got there the clattering had got louder and the engine was also making odd hissing and popping noises on idle.

Sunday morning I reset the tappets. Some had closed up slightly and some had opened up but none were way out. I then drove 50 miles around the Glasgow area followed by the 250 miles home.

At no point did I notice any loss of power - I was still blatting along the motorway at *coughcough* MPH as per usual, overtaking BMWs and Mercedes. ;)

When I got home the idle was quite rough, and the odd noises were still there. I went to work and back today as normal.

Tonight I finally did a compression test. The results were as follows:

Dry: 130 90 90 95

Wet: 150 115 85 80

Off with her head!

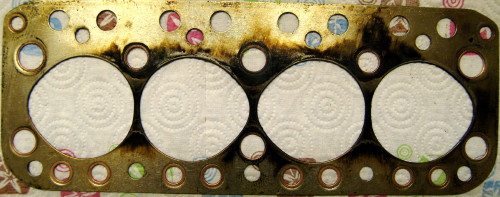

There seems to be evidence of head gasket leakage between all four cylinders. No erosion or missing bits, but there are large black sooty marks on the block and the gasket that weren't there when I fitted the head.

Another odd thing is that although the plugs are pretty clean, there's loads of heavy carbon deposits on the pistons, combustion chambers, and valves. Even the tops of the inlet valves have hard black deposits on them. Everything was spotless when I assembled it and it's only done about 5000 miles since then, much of it at fast motorway speeds!

There's also some very slight pock-marking on the sealing faces of the exhaust valves. I suspect they may not be the hardened "unleaded" type, even though the head was supposedly converted before I bought it. I'm hoping it really does have hardened seats - it's a bit hard to tell.

Any suggestions? I'm considering replacing the exhaust valves with new unleaded ones, I'll definitely clean all the coke off and regrind the valves, and I'm going to borrow a large straight-edge tomorrow to try to check the flatness of the head. I'm wondering whether to try slightly increasing the torque used on the head nuts.