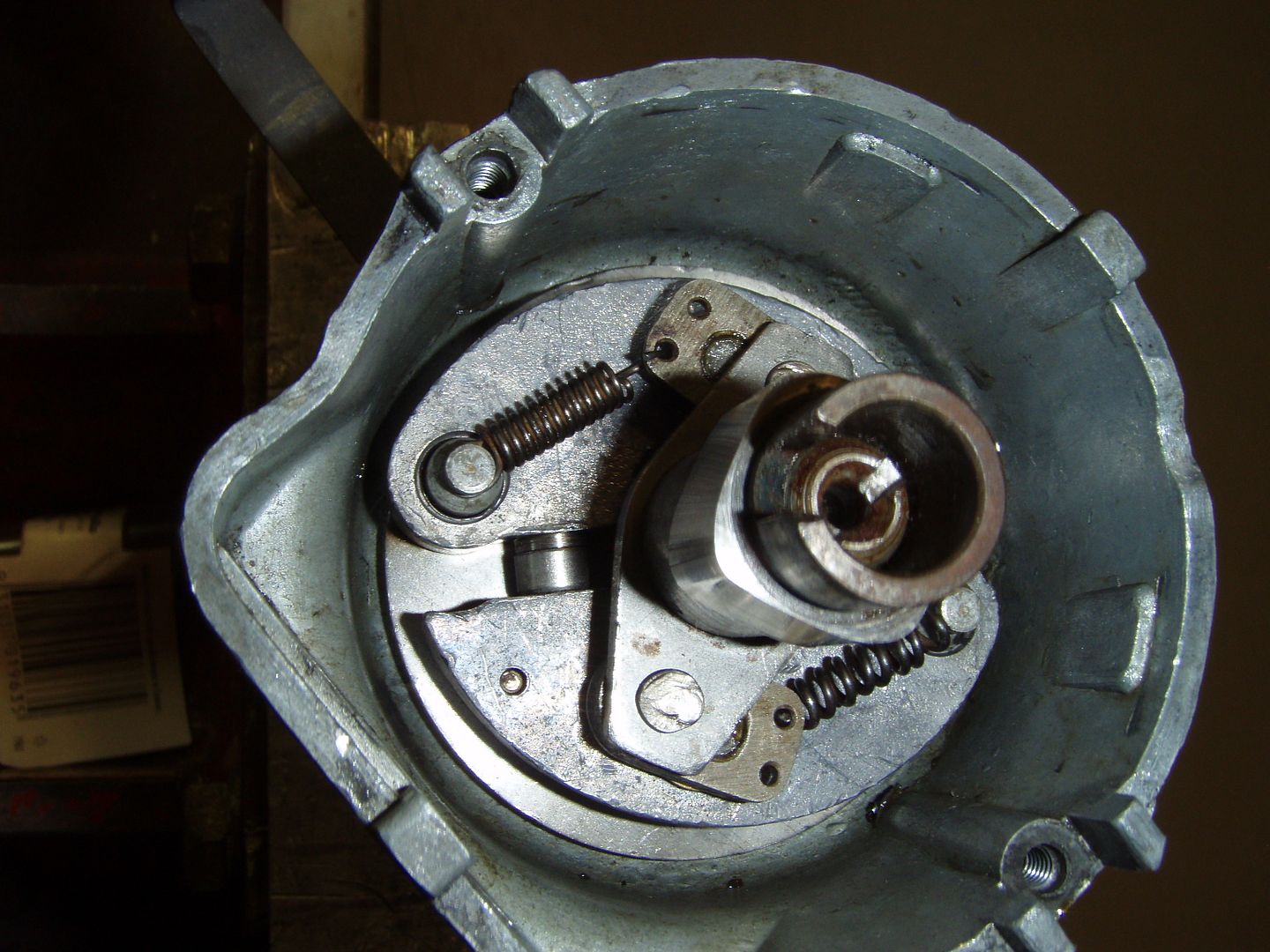

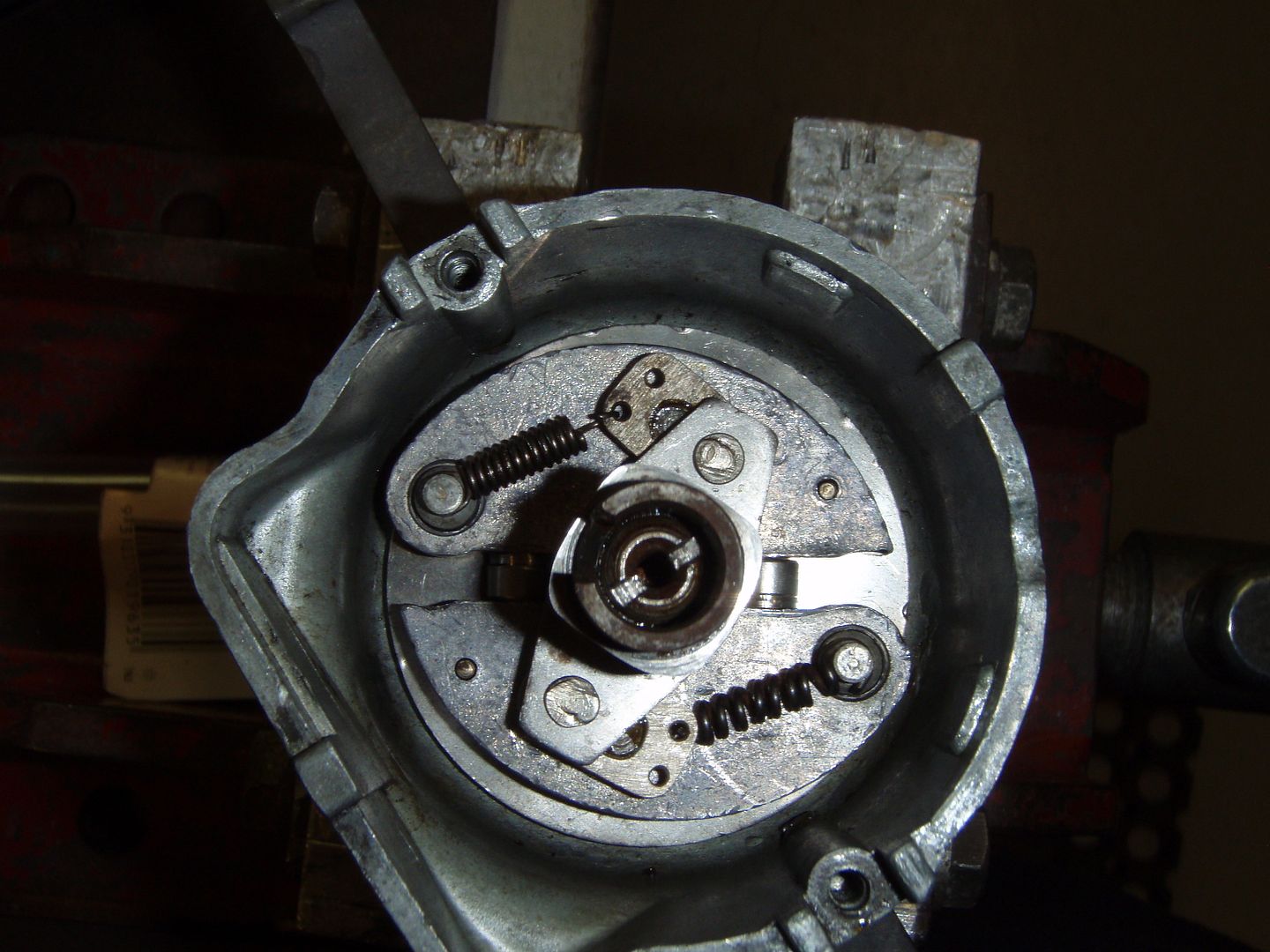

I do not have any knowkedge of the validity of 36 deg. because I have never investigated it. It does seem a lot though. At present my static advance at 900 RPM is 4.5 deg. - distributor advance is restricted to 4.0 deg. (8 engine). I know these settings are precise because my blower at 6000 RPM consumes 12.3 HP. There is no way I could expect the Woodfuf key to take this load especially with the alloy pulley I made. I set the centre of the dividing head of the mill to align with the centre of the quill. Then holding the crank in the chuck TDC was determined with a dial gauge on a crank pin journal by rotating the crank to obtain maximum reading on a dial gauge then locking the dividing head. A 4.0 mm. keyway slot was milled for the full length of the crank nose. The pulley was then fitted and a groove machined at TDC and filled with paint. This is how I know my TDC marks are correct. Even if they wern't I measured the timing after getting home for future reference. The degree of distributor advance on the 23D4 Cooper disy I am using is restricted by a sleeve fitted over the bob weight limiting pin. See pic. For the original DKYH4A dissy it was limited by screwing socket head screws into the lead weights with appropriate washers to obtain 4 deg. adv. This dissy is carried as a spare with known advance characterestics. I don't seem to have any problem seeing the timing marks with the timing light I am using.

Bob